From PET Bottles to High Performance Fabrics: The Journey of Recycled Plastics

The Initial Collection Phase

The recycling process begins with the crucial initial collection phase, where individuals and businesses diligently separate recyclable materials from their general waste. This meticulous sorting is a fundamental step, as the quality of the final recycled product depends heavily on the accuracy and thoroughness of this initial separation. Proper sorting ensures that contaminants don't mix with the recyclables, which can compromise the entire process and render the materials unusable.

Material Sorting and Processing

Once collected, the recyclables undergo a rigorous sorting and processing phase. This often involves complex machinery and human intervention to separate different types of materials based on their composition. This meticulous process is essential to ensure that the different materials are segregated and prepared for further processing. For example, different types of plastics, metals, and papers must be separated to avoid contamination and ensure efficient processing.

Cleaning and Preparation

A crucial step in the recycling process is the cleaning and preparation of the collected materials. This stage involves removing any contaminants, such as food scraps, dirt, or other debris that may have clung to the recyclables during collection. These contaminants can negatively impact the quality of the recycled material and make it unsuitable for reuse. Proper cleaning ensures that the recycled material is fit for reuse in manufacturing processes.

Material Processing for Reuse

The processed materials then enter the material processing phase. This phase involves grinding, shredding, or melting the materials to prepare them for reuse in manufacturing processes. Depending on the material, specialized machinery and techniques are used to modify the form and condition of the recyclables. This meticulous preparation is essential for efficient and effective reprocessing into new products.

Manufacturing New Products

After processing, the materials are ready for use in manufacturing new products. This stage involves utilizing the recycled materials as raw materials for various products, from packaging to construction materials. The recycled materials are often blended with virgin materials to create new products with desired qualities. This innovative process helps conserve resources and reduces the environmental impact of manufacturing.

Quality Control and Monitoring

Throughout the entire recycling process, quality control and monitoring are essential to ensure that the recycled materials meet the necessary standards for reprocessing and reuse. Regular checks and inspections ensure that contaminants are minimized, and that the recycled materials are consistent in quality. Maintaining high-quality standards is crucial to ensure that the recycled materials can be used effectively in the production of new products. This rigorous monitoring process also helps identify any potential issues early on and prevent them from escalating.

Environmental Impact and Sustainability

The recycling process plays a vital role in promoting environmental sustainability. By reducing the demand for virgin resources, recycling conserves natural resources, minimizes waste generation, and significantly reduces the environmental impact of manufacturing. Recycling is a crucial step in mitigating climate change and preserving our planet for future generations. This process also helps to conserve energy and reduce pollution associated with the production of new materials from raw resources.

From Bottles to Fabrics: The Potential of Recycled Polyester

From Plastic to Polyester: A Sustainable Transition

The ubiquitous nature of plastic bottles has left a significant environmental footprint, contributing to overflowing landfills and polluting our oceans. This pervasive presence necessitates a radical shift towards sustainable alternatives. One promising avenue lies in repurposing plastic waste into valuable materials, such as fabrics. This innovative approach offers a compelling solution to the plastic problem, while simultaneously reducing our reliance on virgin resources and minimizing the environmental impact of textile production.

The process of transforming plastic bottles into fabrics involves a complex series of steps, from collection and sorting to chemical processing and fiber creation. This intricate transformation allows us to leverage the inherent strength and versatility of plastic while mitigating its detrimental effects on the environment. The potential for creating durable and aesthetically pleasing fabrics from recycled plastic is truly remarkable.

The Economic Advantages of Recycled Textiles

The economic benefits of transitioning to recycled textiles are substantial. The reduction in the demand for virgin materials translates to lower production costs, fostering a more sustainable and cost-effective textile industry. This shift encourages innovation and creates new opportunities for entrepreneurs and businesses committed to environmental responsibility.

Furthermore, the increased demand for recycled materials stimulates the development of new technologies and processes, fostering economic growth and job creation in the recycling and textile sectors. This creates a virtuous cycle, promoting both economic development and environmental sustainability.

Environmental Impact of Traditional Textile Production

Traditional textile production often relies heavily on fossil fuels, leading to significant greenhouse gas emissions. The process of growing cotton, a common textile material, requires vast amounts of water and pesticides, contributing to water pollution and ecological damage.

Furthermore, the disposal of textile waste often ends up in landfills, contributing to the ongoing plastic and textile pollution problem. This highlights the urgent need for a systemic shift towards more sustainable and environmentally friendly textile production methods.

The Role of Innovation in Sustainable Textiles

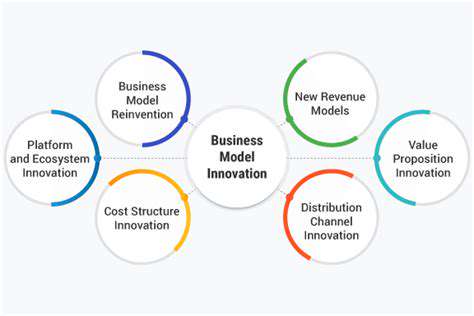

Technological advancements are crucial in driving the transition towards sustainable textiles. Innovative techniques, such as advanced recycling processes and the development of biodegradable materials, play a pivotal role in minimizing the environmental impact of the textile industry.

These innovations are essential for creating a truly circular economy in textiles, where waste is minimized and resources are utilized effectively.

The Social Responsibility of the Textile Industry

The textile industry bears a significant responsibility for its impact on society and the environment. Implementing sustainable practices necessitates a commitment to ethical labor standards and responsible sourcing of raw materials.

This includes ensuring fair wages, safe working conditions, and environmentally sound production methods for textile workers, both in the development and manufacturing stages.

Consumer Awareness and Demand

Consumers play a vital role in driving the demand for sustainable textiles. Educating consumers about the environmental impact of traditional textile production and the benefits of recycled materials is paramount.

Promoting awareness about the importance of choosing sustainable and recycled materials will encourage businesses to adopt more environmentally friendly practices. This shift in consumer preference fosters a positive feedback loop that encourages innovation and sustainability in the textile industry.

The Future of Sustainable Fashion

The future of fashion hinges on our ability to embrace sustainability. By shifting towards recycled and biodegradable materials, we can create a more environmentally responsible and economically viable textile industry.

This transition to sustainable practices is not just about saving the environment; it's about building a more equitable and prosperous future for all.

Rainwater harvesting is the process of collecting and storing rainwater for later use. This method offers a sustainable and environmentally friendly alternative to traditional water sources, especially in areas facing water scarcity or high water costs. It's a vital practice for conserving water resources and reducing reliance on municipal water supplies. By utilizing rainwater, communities and individuals can significantly decrease their environmental footprint and contribute to a more sustainable future.

Beyond Fabrics: Exploring Diverse Applications

Beyond the Basics: A Look at Textile Innovations

Textiles are far more than just fabrics; they represent a vast and evolving field encompassing a wide range of materials and applications. From advanced performance fabrics designed for specific athletic needs to innovative materials with unique properties, the possibilities are constantly expanding. This exploration delves into the exciting realm of textile science, highlighting the creative and technical advancements shaping the future of textiles.

Beyond traditional cotton, linen, and silk, modern textiles incorporate a multitude of materials with remarkable properties. These include synthetic fibers like nylon and polyester, as well as natural fibers like bamboo and hemp, each offering unique advantages in terms of durability, comfort, and sustainability.

Sustainable Practices in Textile Production

The textile industry is increasingly recognizing the importance of environmental sustainability. Companies are actively seeking ways to reduce their environmental footprint by adopting eco-friendly practices, such as using recycled materials and minimizing water and energy consumption during production. This shift towards sustainability is not just about reducing waste but also about creating a more responsible and ethical supply chain.

Furthermore, the growing demand for sustainable textiles is driving innovation in fiber sourcing and manufacturing processes. Consumers are increasingly demanding transparency and traceability in their textile purchases, pushing companies to adopt more sustainable practices throughout their operations.

Innovative Applications of Textile Materials

Textiles are no longer confined to traditional apparel applications. Their versatility extends to diverse fields like aerospace, automotive, and healthcare. High-performance fibers are used in aerospace applications for lightweight yet incredibly strong components, while innovative materials in the automotive sector enhance safety and comfort.

In healthcare, textiles play a crucial role in medical devices and wound care. The development of advanced textile materials with specific properties, such as antimicrobial or biocompatible characteristics, is revolutionizing these sectors and improving patient outcomes.

The Future of Textile Design and Technology

The future of textiles is bright, promising even more innovative applications and groundbreaking advancements. Digital printing techniques and 3D textile printing are transforming the design and manufacturing process, allowing for greater customization and personalized products. These technologies also hold the potential to democratize textile production, making it more accessible to smaller businesses and individual creators.

The integration of smart technologies into textiles is another exciting area of development. Imagine fabrics that adapt to temperature changes, monitor vital signs, or even generate electricity. These advancements are blurring the lines between textiles and technology, opening up a world of possibilities for future applications.

Textiles and the Global Economy

The textile industry plays a significant role in the global economy, impacting employment, trade, and economic development in numerous countries. Understanding the complex interplay between textile production, trade policies, and global markets is crucial for navigating the challenges and opportunities within this sector.

The industry's influence extends beyond manufacturing, affecting related industries such as design, retail, and logistics. A deeper understanding of the global textile landscape is vital for fostering sustainable and responsible growth within this significant economic sector.