Measuring the Environmental Impact of Circularity: New Metrics

Key Metrics for Assessing Circularity's Environmental Benefits

Material Circularity

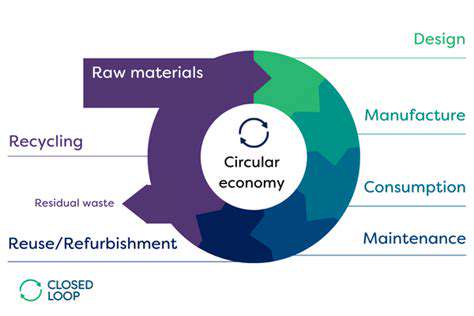

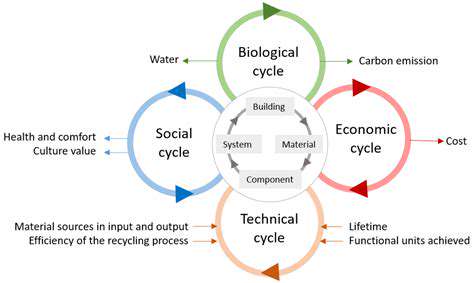

When evaluating circular systems, material circularity stands out as a fundamental measure. It examines how effectively materials are repurposed, recycled, or recovered after a product's useful life ends. This metric reveals what percentage of materials remain in active use rather than ending up in landfills or incinerators. Its importance lies in directly influencing both resource conservation and ecological footprints. Systems demonstrating high material circularity typically feature efficient processes for recirculating materials, thereby reducing dependence on newly extracted resources.

To quantify this aspect, analysts track material movement through every phase of a product's existence. Key measurements include the recycled content percentage in newly manufactured goods, material retrieval rates from waste systems, and the total volume of materials maintained within economic circulation. Accurate information gathering and interpretation form the backbone of successful circularity programs.

Economic Circularity

This dimension evaluates financial advantages stemming from circular practices, including lowered material expenses, enhanced operational efficiency, and novel income sources. It investigates how circular models stimulate economic development through innovation, employment generation, and sustainable expansion. Evaluations consider the monetary value obtained from material reuse, savings from waste reduction, and the viability of circular-based business models.

One standout feature involves the emergence of markets specializing in material recovery and repurposing. These markets enable businesses and inventors to transform waste into profitable ventures while addressing environmental concerns. Assessing these economic factors helps determine the practicality and appeal of circular economic approaches.

Environmental Circularity

This measurement focuses on ecological improvements resulting from circular practices, particularly regarding resource conservation, emission reductions, and pollution control. It assesses how waste minimization, efficient resource utilization, and cleaner production methods contribute to environmental health. Specific considerations include diminished raw material consumption, lower emissions from waste processing, and enhanced environmental quality through pollution mitigation.

Effective measurement requires tracking multiple indicators like water usage reductions, landfill diversion rates, and emission declines. These data points collectively illustrate the environmental efficacy of circular practices. Prioritizing these impacts ensures the long-term sustainability of circular economic models.

Challenges and Considerations in Developing Circularity Metrics

Defining Scope and Boundaries

Clear parameter definition proves essential for reliable circularity assessments. This entails specifying which product lifecycle phases to include, relevant geographic or supply chain parameters, and particular materials or processes under examination. Vague parameters can distort findings, complicating comparisons between different initiatives. For instance, comparing a company analyzing only packaging recycling against another assessing full product lifecycles yields misleading results. Consistent, well-defined parameters ensure metric validity and comparability.

Additionally, comprehensive material flow mapping throughout systems remains critical. This encompasses documenting all inputs, outputs, and transformations across a product's lifespan. Achieving this requires cooperation among suppliers, producers, and end-users. Thorough material tracking from origin to disposal, supported by rigorous data practices, enables complete understanding of circular performance. System-wide perspectives, rather than isolated components, prove necessary for developing impactful resource efficiency strategies.

Data Availability and Accessibility

Accurate metrics depend on reliable data, yet obtaining comprehensive lifecycle information presents significant hurdles. Many organizations lack complete supply chain visibility, impeding material tracing from source to final disposition. Addressing this demands investments in data infrastructure and enhanced stakeholder collaboration. Implementing uniform data protocols and utilizing digital tools for collection and analysis represent crucial steps forward.

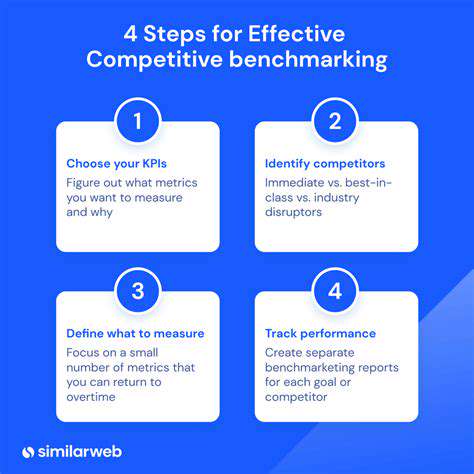

Beyond availability, data comparability poses additional challenges. Diverse organizational methodologies hinder cross-industry or regional comparisons. Establishing standardized approaches through multi-stakeholder cooperation can create transparent frameworks enabling meaningful benchmarking. Improved data access and consistency remain vital for advancing circular economic models.

The Future of Measuring Circularity Impact

Defining Circularity Metrics

Environmental impact measurement necessitates comprehensive frameworks for evaluating circular economy components. This includes analyzing material flows, waste minimization, and recycling effectiveness. Sector-specific yet adaptable metrics must assess circular initiatives from product design through end-of-life management. Transparent, verifiable measurements ensure accountability while accommodating industry variations.

Consistent metric development enables progress tracking and identifies improvement opportunities during circular transitions. Comparative analyses of different approaches can drive innovation and establish best practices across sectors.

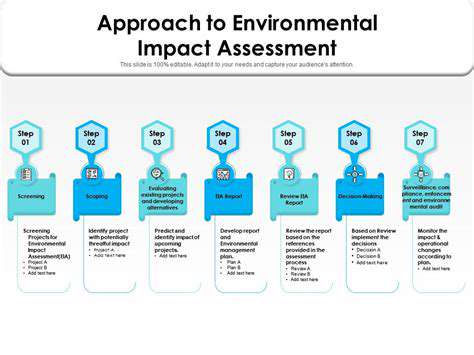

Lifecycle Assessment and Circularity

Lifecycle assessments (LCAs) provide critical insights into product environmental footprints from creation to disposal. Integrating circular principles into LCAs reveals how design and production choices influence overall impacts. Such analysis pinpoints optimization opportunities, from sustainable material selection to designs facilitating component recovery.

Data Collection and Analysis for Circularity

Comprehensive data gathering regarding material flows, waste generation, and recycling performance forms the foundation for accurate circularity evaluation. Standardized data collection across all lifecycle stages enables meaningful cross-industry and regional comparisons. Sophisticated data management systems become indispensable for monitoring progress and directing interventions.

The Role of Technology in Circularity Measurement

Innovative technologies like blockchain and IoT sensors revolutionize circularity tracking capabilities. Blockchain ensures tamper-proof material flow documentation across supply chains, while sensors enable real-time product condition monitoring. These tools provide actionable insights for optimizing resource utilization and minimizing waste generation.

Benchmarking and Standards for Circularity

Global sustainability efforts require unified circularity benchmarks and standards. Developing consistent metrics, reporting formats, and data specifications through international cooperation facilitates knowledge exchange and drives innovation. Such standardization accelerates circular economy adoption worldwide.

Policy and Regulatory Frameworks for Circularity Measurement

Governments significantly influence circular transitions through supportive policies and regulations. Effective frameworks should incentivize circular practices, standardize measurement methodologies, and ensure transparent impact reporting. Addressing data collection and interpretation challenges makes metrics accessible to all stakeholders.

The Future of Circularity Measurement

Future assessment systems will adopt more integrated approaches, incorporating social and economic dimensions alongside environmental factors. This holistic perspective better captures circularity's full value in creating sustainable, equitable societies. Evolving methodologies must accommodate technological advancements and emerging needs to maintain relevance.