Sustainable Sneaker Brands: Style That Doesn't Cost the Earth

Sustainable Materials: Beyond the Canvas

The New Era of Material Innovation

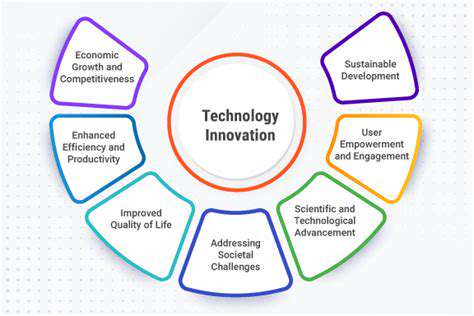

As environmental consciousness takes center stage globally, industries are undergoing a radical transformation in their material selection. Where once cost and convenience dictated choices, today's manufacturers are prioritizing planet-friendly alternatives that satisfy both ecological and performance requirements. This paradigm shift represents more than temporary market adjustment—it's a complete reimagining of production philosophy.

Several powerful forces drive this transformation, including heightened public understanding of ecosystem fragility, evolving governmental policies, and shifting corporate responsibility benchmarks. Modern consumers actively seek products reflecting their environmental values, compelling businesses to integrate sustainability into their core operations rather than treating it as a secondary consideration.

Revolutionary Substitutes for Conventional Materials

The materials landscape is witnessing an explosion of creative solutions challenging traditional options. Plant-derived polymers manufactured from agricultural byproducts are emerging as serious contenders against conventional plastics, particularly in packaging applications. These innovations demonstrate comparable functionality while drastically reducing environmental harm.

The material revolution extends far beyond plastic alternatives, encompassing repurposed materials like reprocessed ocean plastics that give new life to waste streams. These approaches not only conserve natural resources but also demonstrate significant economic advantages through reduced material acquisition costs.

Natural fibers including fast-growing bamboo and resilient hemp are transforming textile and construction sectors. Their rapid growth cycles, minimal resource requirements, and biodegradable nature make them superior choices for numerous applications, from clothing to building materials.

The Ripple Effects of Material Transformation

Adopting sustainable materials creates waves across economic and social spheres. The burgeoning green materials sector is generating employment in research, development, and manufacturing—positions that will define the workforce of tomorrow. These emerging industries represent the vanguard of economic evolution, combining profitability with planetary stewardship.

This materials shift is fundamentally altering economic models, moving us toward circular systems where waste becomes feedstock. Such systems enhance resource efficiency while building economic resilience against commodity shortages and price volatility.

From a public health perspective, sustainable materials reduce exposure to toxic substances prevalent in conventional products. This benefit alone justifies the transition, as it promises healthier living environments for current and future populations.

Conscientious Manufacturing: Ethics at the Core

Human-Centric Production Standards

At the heart of ethical manufacturing lies respect for human dignity. Providing compensation that supports decent living standards, maintaining hazard-free workplaces, and honoring collective bargaining rights aren't optional—they're moral imperatives. When workers receive fair treatment, they become partners in quality rather than expendable resources, creating virtuous cycles that benefit all stakeholders.

Organizations embracing these principles frequently experience enhanced operational stability through lower staff turnover and stronger team cohesion. The resulting productivity gains and quality improvements demonstrate that ethical treatment isn't just morally correct—it's commercially astute.

Ecological Manufacturing Processes

Truly responsible production demands rigorous environmental protocols. This encompasses everything from energy-efficient operations to closed-loop waste systems and clean technologies. Safeguarding ecosystems while meeting production needs requires constant innovation and commitment. Forward-thinking companies recognize that environmental responsibility extends beyond compliance to active regeneration.

The economic case for sustainable manufacturing grows stronger daily, with energy savings and waste reduction delivering measurable bottom-line benefits. These financial advantages complement the ecological gains, proving that planetary and corporate health are mutually reinforcing.

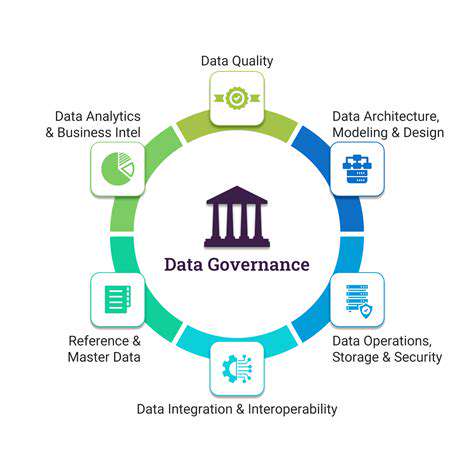

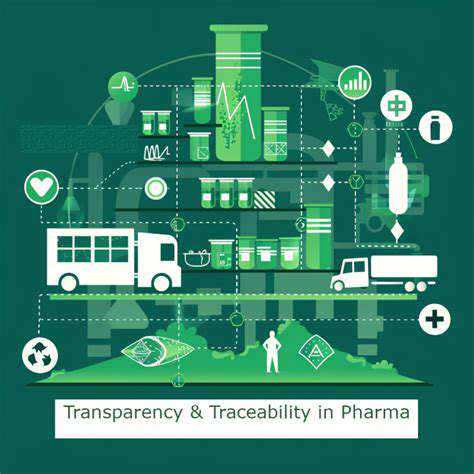

Radical Transparency in Operations

Building consumer trust demands unprecedented openness about production practices. Detailed supply chain disclosures allow verification of ethical claims, while stakeholder engagement fosters collaborative improvement. In today's informed marketplace, transparency isn't optional—it's the price of admission for responsible brands. This openness enables consumers to align purchases with principles, creating market incentives for ethical business practices.

Moreover, transparent operations encourage industry-wide benchmarking, raising standards across sectors as companies learn from each other's best practices.

The Future of Footwear: Walking Lightly on the Planet

Why Sustainable Footwear Matters

Conventional shoe manufacturing ranks among the most resource-intensive industries, employing harmful chemicals and generating substantial waste streams. Opting for sustainable footwear represents a powerful consumer choice with measurable environmental impact. As awareness grows, buyers increasingly demand products that reflect their ecological values, driving innovation across the sector.

This shift isn't merely about materials—it's about rethinking the entire product lifecycle, from design to disposal. Sustainable brands are proving that performance and responsibility aren't mutually exclusive, but rather complementary qualities in modern footwear.

The Transparency Imperative

Leading eco-conscious footwear companies distinguish themselves through complete supply chain visibility. They provide detailed insights into material sources, production methods, and labor conditions, empowering consumers to make fully informed decisions. This level of disclosure represents a new standard in corporate accountability, moving beyond greenwashing to authentic sustainability.

Material Innovations in Footwear

The most exciting developments in sustainable shoes come from material science. Manufacturers are incorporating everything from recycled ocean plastics to plant-based leather alternatives and regenerative agricultural products. These materials match or exceed conventional options in durability and performance while dramatically reducing environmental harm.

Responsible Manufacturing Practices

Eco-friendly shoe producers implement numerous process innovations—water recycling systems, renewable energy use, and waste-minimization techniques—that collectively reduce their environmental footprint. These measures demonstrate that sustainability extends beyond materials to every aspect of production.

Designing for Longevity

Sustainable footwear emphasizes timeless design and durable construction to maximize product lifespan. This approach counters disposable fashion culture, reducing overall consumption while delivering better value to consumers. High-quality sustainable shoes often become wardrobe staples rather than temporary trends.

The Human Dimension

Ethical footwear brands ensure fair compensation and safe conditions throughout their supply chains. They view workers as valued contributors rather than cost centers, recognizing that human welfare is inseparable from product quality and brand integrity.

The Bigger Picture

Choosing sustainable footwear creates positive ripple effects across ecosystems and communities. Each purchase supports cleaner production methods, fair labor practices, and innovative material development. Consumers wield tremendous power to shape industry practices through their buying decisions. As more people prioritize sustainability, the entire market shifts toward responsible production.