The Importance of Durability in Sustainable Fashion

Understanding the Problem: The Wasteful Cycle

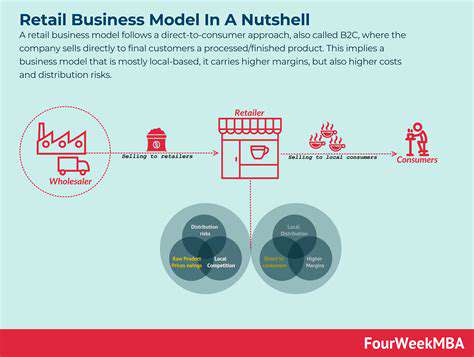

The contemporary retail environment thrives on planned obsolescence and artificial trend cycles. This engineered disposability generates staggering textile waste - the equivalent of one garbage truck of clothes burned or landfilled every second globally. The environmental toll includes microplastic pollution, chemical runoff, and carbon emissions from perpetual production, demanding urgent systemic change.

Durability: A Sustainable Solution

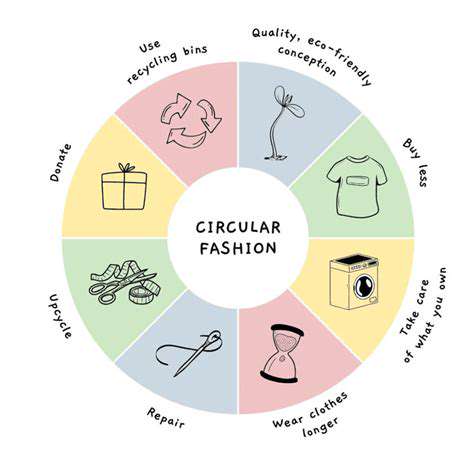

Designing for longevity represents fashion's most effective waste-reduction strategy. Durable construction, timeless aesthetics, and modular design allow garments to transcend seasonal cycles. This approach requires rethinking traditional business models, shifting from volume-based to value-based production that prioritizes product lifespan over unit turnover.

Economic Advantages of Durable Goods

While durable garments command higher initial costs, their cost-per-wear often proves significantly lower than disposable alternatives. Consumers benefit from reduced replacement frequency, while manufacturers gain from decreased production volumes and enhanced brand loyalty. This economic realignment supports living wages for skilled workers rather than exploiting cheap labor markets.

Environmental Impact of Reduced Waste

Extending a garment's active life by just nine months reduces its carbon, water, and waste footprints by 20-30% each. Durability directly addresses fashion's environmental crises by shrinking resource extraction, manufacturing emissions, and post-consumer waste simultaneously. These cumulative benefits make longevity the most comprehensive sustainability solution available.

Design Considerations for Durability

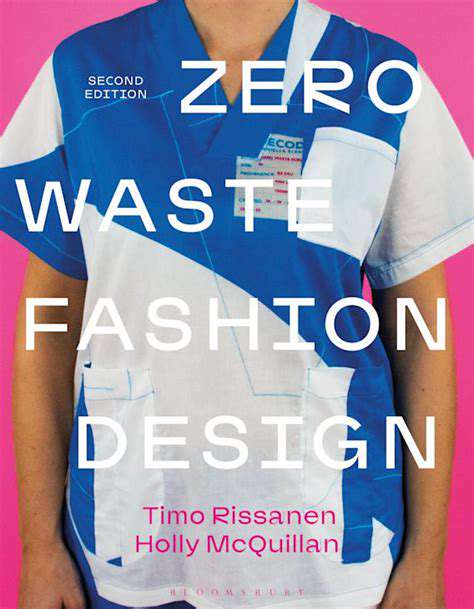

Thoughtful design integrates multiple durability strategies: generous seam allowances for alterations, colorfast dyes, and modular components that allow for repair or updating. Designers must balance aesthetic vision with structural integrity, creating pieces that remain relevant and functional across changing trends and body fluctuations.

Consumer Responsibility and Choices

Conscious purchasing decisions drive industry transformation. Prioritizing brands with transparent supply chains, repair programs, and material guarantees signals market demand for durability. Developing basic mending skills further extends garment life, while proper care techniques preserve material integrity for maximum wear.

The Future of Durability: Innovation and Collaboration

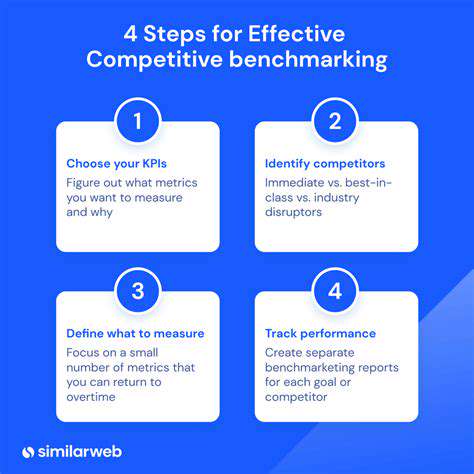

Emerging technologies like blockchain material tracking and AI-assisted design optimization promise new durability frontiers. Cross-industry partnerships can accelerate innovations in biodegradable reinforcements and self-repairing textiles. Ultimately, systemic change requires cooperation between policymakers, manufacturers, and consumers to reshape fashion's fundamental economics around longevity.

When evaluating product longevity, material selection and construction methods form the foundation for durability. Compromising on either element inevitably leads to premature product failure regardless of other quality indicators. Consider denim jeans using premium Japanese fabric but assembled with weak thread - the superior material potential remains unrealized. These foundational choices create ripple effects throughout a product's lifecycle, influencing everything from repair feasibility to eventual recyclability.

The Ripple Effect: Durability and the Fashion Industry's Evolution

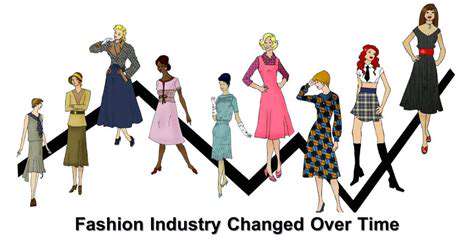

Durability in the Face of Change

Contemporary fashion must reconcile ephemeral trends with enduring quality. Adaptive design principles allow garments to evolve with wearers rather than becoming obsolete. This requires balancing current aesthetics with timeless construction, creating pieces that remain relevant across shifting style landscapes.

Historical analysis reveals how quality benchmarks have fluctuated with industrialization. Rediscovering pre-industrial craftsmanship techniques offers solutions for modern durability challenges, blending traditional knowledge with contemporary materials science to create hybrid approaches to longevity.

The Interconnected Web of Systems

Durability initiatives affect entire ecosystems - improved garment lifespan reduces pressure on cotton farms, decreases dye pollution, and alleviates landfill strain. These interconnected benefits demonstrate how targeted improvements in product durability can generate disproportionate positive impacts across multiple sectors.

Comprehensive lifecycle analysis reveals unexpected durability benefits, such as how longer-lasting wool garments naturally biodegrade while synthetic alternatives persist as microplastics. These systemic considerations must inform future durability standards and certifications.

Building Resilient Infrastructure

Supporting durability requires reimagining fashion infrastructure - from establishing regional repair networks to developing circular material recovery systems. Localized craftsmanship hubs can reduce transportation emissions while preserving endangered tailoring skills, creating distributed systems more resilient than centralized fast-fashion models.

The Role of Human Capital

Durability demands skilled labor at every stage - from material scientists developing longer-lasting fibers to artisans executing precision construction. Investing in textile education creates economic stability while advancing sustainability goals, proving environmental and social progress need not conflict.

The Importance of Adaptable Governance

Policy frameworks must evolve to support durability transitions. Extended producer responsibility laws and durability labeling requirements create accountability missing from current voluntary initiatives. These measures help align corporate incentives with environmental necessities, driving innovation toward meaningful longevity solutions.