The Science Behind Textile Recycling Processes: New Discoveries

Mechanical Recycling for Fiber Recovery: A Deep Dive

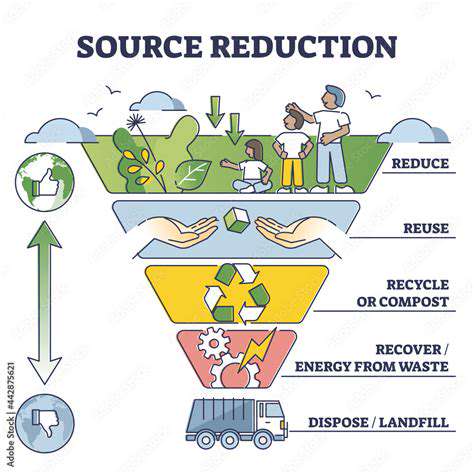

Mechanical recycling, a cornerstone of textile sustainability, relies on physical processes to break down fabrics into reusable fibers. This approach involves shredding, thorough cleaning, and contaminant removal to prepare materials for new applications. Unlike energy-intensive chemical methods, mechanical recycling offers a simpler, more eco-friendly alternative. However, the resulting fiber quality depends heavily on both the original fabric composition and the recycling efficiency. Typically, these reclaimed fibers find use in products like insulation, furniture padding, or composite materials where high-grade textiles aren't essential.

Textile types behave differently during mechanical processing. Natural fibers such as cotton and linen generally maintain better integrity than synthetic blends. Mixed materials containing polyester or nylon present particular challenges, frequently yielding lower-grade output. Current research focuses on refining mechanical techniques to accommodate diverse fabric combinations more effectively, which could revolutionize how we repurpose textile waste and support industry sustainability goals.

Challenges and Considerations in Fiber Recovery

Contaminant removal poses a major hurdle in mechanical textile recycling. Zippers, buttons, and fabric tags can impair equipment and diminish output quality. Advanced sorting systems are becoming indispensable for producing competitive recycled materials. These technologies help separate unwanted elements while preserving fiber integrity throughout the recycling chain.

The process inherently affects fiber characteristics. Recycled strands often lack the strength and consistency needed for premium applications like garment production. This limitation demands creative thinking about alternative uses that capitalize on the material's properties while acknowledging its constraints. Developing novel applications for these fibers represents a critical step toward minimizing textile waste.

Optimizing Fiber Recovery for Sustainability

Enhancing fiber recovery efficiency requires multifaceted improvements. Next-generation sorting systems that accurately identify material compositions could dramatically upgrade recycling outcomes. These technological advances are particularly valuable for handling complex fabric blends that currently challenge conventional methods.

System-wide optimization from collection through processing is equally vital. Improving textile waste sorting at the source and educating consumers about proper disposal can ensure better quality input for recycling facilities. Community engagement initiatives and convenient return programs may significantly increase participation in textile recycling efforts.

Bio-based Textile Recycling: A Promising Future

Bio-Based Textiles: A Sustainable Alternative

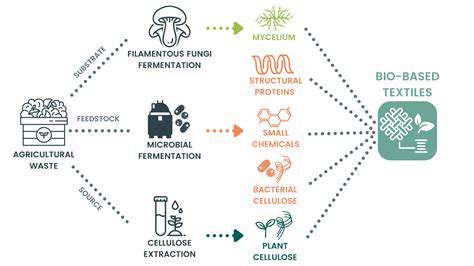

Plant-derived textiles represent a paradigm shift in sustainable fashion. These renewable materials, sourced from crops and agricultural byproducts, typically biodegrade more readily than petroleum-based alternatives. This transition marks a pivotal move toward circular economic models in apparel production. The growing eco-conscious consumer base continues to fuel remarkable innovations in this sector.

Scientific exploration has uncovered numerous bio-based possibilities, ranging from advanced cellulose fabrics to protein-derived fibers, each offering distinct characteristics for various applications. These discoveries are reshaping material science in the fashion industry.

Recycling Challenges in the Textile Industry

Modern fabric mixtures create substantial recycling obstacles. The prevalence of hybrid materials combining synthetic and natural fibers renders conventional recycling approaches inadequate. This complexity makes separating and processing textiles both expensive and technically demanding.

Additional contamination from food residues or packaging materials further degrades recyclate quality. Such impurities frequently disqualify recycled output from premium applications, limiting its commercial potential.

The Importance of Chemical Recycling

Chemical depolymerization offers a breakthrough solution for challenging textile waste. This method decomposes materials at the molecular level, enabling regeneration of pristine-quality fibers. By overcoming mechanical recycling's limitations, this approach can handle intricate material combinations previously considered unrecyclable.

The scalability of chemical recycling technologies could fundamentally transform textile waste management, converting discarded clothing into valuable feedstock. Continued investment in this field remains essential for achieving these sustainability goals.

Innovative Approaches to Bio-Based Recycling

Emerging bio-recycling techniques show particular promise for sustainable textiles. Enzymatic processes that selectively dismantle biopolymer structures could unlock unprecedented recycling efficiency. This methodology may enable complete valorization of bio-based textile components.

Material design also plays a crucial role. Engineers are developing inherently recyclable bio-textiles through strategic molecular architecture and biodegradable modifiers. These design innovations aim to simplify future recycling processes while maintaining material performance.

The Role of Consumer Awareness and Policy

Informed consumers significantly influence sustainable textile adoption. Educating the public about clothing's environmental impact and recycled material benefits can drive meaningful market transformation. This includes highlighting how purchasing decisions affect the entire product lifecycle.

Strategic policy interventions can dramatically accelerate bio-based textile adoption. Legislative support for recycling infrastructure and research funding can stimulate innovation while helping manufacturers transition to sustainable practices.

Economic and Social Benefits of Bio-Based Recycling

The bio-recycling sector offers substantial socioeconomic advantages. New career opportunities in green technology and waste management can revitalize traditional textile regions. This economic diversification proves especially valuable for communities grappling with industrial pollution challenges.

Transitioning to circular textile systems enhances industry resilience while creating sustainable employment. The potential socioeconomic ripple effects of this transformation could benefit multiple sectors beyond fashion alone.