Designing for Disassembly: The Key to Future Proof Circular Products: New Principles

Employing modular design principles allows for the separation of components into independent, easily removable units. This modularity facilitates the disassembly process by isolating individual parts and minimizing the need for intricate or complex interventions. Components can be replaced or upgraded without impacting the integrity of the entire system, reducing the overall cost and time spent on repairs or replacements.

The key to successful modularity lies in designing interfaces that allow for straightforward connection and disconnection. Standardized connectors and easily accessible fastening mechanisms are essential for efficient disassembly and future modifications.

Strategic Material Selection

Choosing appropriate materials for your product is crucial in the context of disassembly. Materials that are easily separable and recyclable contribute significantly to a streamlined process. Consider using materials that can be mechanically separated, such as different types of plastics or metals, rather than those that rely on chemical processes for separation. This minimizes environmental impact and simplifies the dismantling process.

Furthermore, materials with consistent properties across the product's lifecycle can minimize variations in the disassembly process. Ensuring that the materials remain stable and predictable throughout the product's lifetime can significantly reduce the complexities involved in handling and separating components.

Standardized Fasteners and Connections

Utilizing standardized fasteners and connection methods simplifies the disassembly process considerably. Common screws, nuts, bolts, and connectors are easier to identify, remove, and replace compared to unique or specialized components. This standardization also allows for the use of readily available tools, further reducing the time and cost associated with the disassembly operation.

Clear Labeling and Component Identification

Implementing a clear labeling system for components is essential for efficient disassembly. Detailed labeling of each part, including its function and location within the assembly, significantly reduces the time required to locate and remove components during the dismantling phase. This clear identification process is critical for ensuring that each component is accurately separated and properly handled during the recycling or reuse process.

Designing for Accessibility

Ensuring components are accessible during the disassembly process is paramount. Avoiding complex geometries that obstruct access or require specialized tools directly impacts disassembly time. Strategically placed access points, clear pathways, and unobstructed component placement minimize the need for intricate maneuvering. This is key to minimizing the risk of damage to components during the separation process and, critically, ensures that the entire disassembly process is as efficient and safe as possible.

Waste Minimization Through Design

Minimizing the generation of waste during the disassembly process is a critical aspect of designing for disassembly. This can be achieved by employing design strategies that reduce the number of different materials or components used. The use of fewer parts inherently reduces the amount of waste produced during the dismantling process, which aligns with sustainability goals. Furthermore, designing for reusability or recyclability can further reduce the overall environmental footprint of the product.

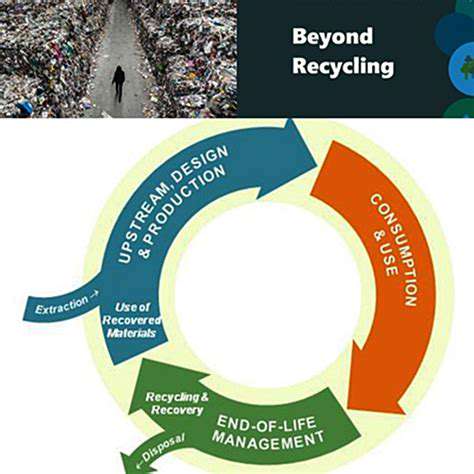

Beyond Recycling: Maximizing Material Recovery and Reuse

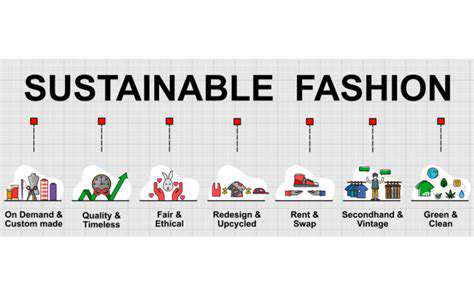

Material Recovery and Upcycling

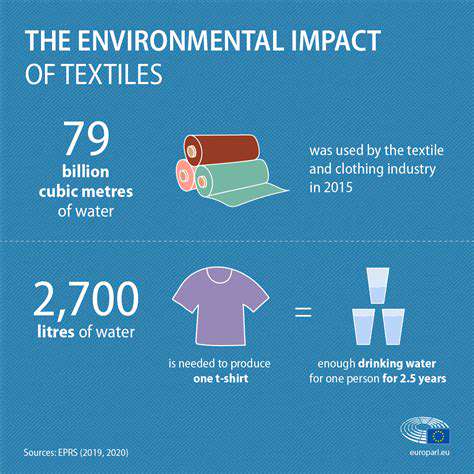

Beyond simply collecting and recycling materials, maximizing material resources involves a multifaceted approach that encompasses Material recovery and upcycling. This approach goes beyond the traditional linear take-make-dispose model, aiming for a more circular economy where resources are kept in use for as long as possible. This means actively recovering valuable materials from waste streams and transforming them into new products, rather than just discarding them.

Material recovery focuses on extracting usable components from discarded items. This can include separating metals, plastics, and paper for reuse in manufacturing processes. By recovering these materials, we significantly reduce the need for extracting virgin resources, lowering our environmental impact.

Innovative Manufacturing Processes

Adopting innovative manufacturing processes is crucial for maximizing material use. These processes can involve designing products with durability and repairability in mind, enabling them to be easily disassembled and reused. By prioritizing design for disassembly, we can effectively extend the lifespan of products and minimize waste generation.

Furthermore, advancements in 3D printing and other additive manufacturing techniques allow for more precise material utilization, minimizing waste during the production process. These technologies can also create customized and personalized products, reducing the need for mass production and its associated waste.

Sustainable Product Design

Sustainable product design plays a vital role in maximizing material resources. This involves designing products from the outset with sustainability in mind, considering the entire lifecycle of the product, from raw material extraction to end-of-life disposal. This proactive design approach emphasizes the need to minimize material use and maximize resource efficiency.

Prioritizing durability, repairability, and recyclability are key components of sustainable product design. Designing products to be easily repaired or upgraded rather than replaced reduces consumption and waste. This approach fosters a culture of responsible consumption and resource management.

Economic and Social Benefits

Maximizing material resources offers significant economic and social benefits. By recovering and reusing materials, businesses can reduce their reliance on expensive raw materials, leading to cost savings and improved profitability. This can create new job opportunities in the material recovery and recycling sectors, boosting the local economy.

A circular economy, built on maximizing material resources, contributes to a more resilient and sustainable society. It fosters innovation, reduces environmental degradation, and creates a more equitable distribution of resources, benefiting both the environment and the community.

The Economic and Environmental Advantages of DfD

Economic Advantages of DfD

Designing for Disassembly (DfD) offers a multitude of economic benefits across various industries. By anticipating the future disassembly process, companies can significantly reduce the costs associated with end-of-life management. This proactive approach minimizes the expenses of material recovery, component repurposing, and waste disposal. DfD strategies often lead to a streamlined and more efficient product lifecycle, reducing the overall cost of production and maintenance throughout the product's lifespan. Furthermore, the ability to reuse components and materials translates into substantial cost savings, particularly in the face of rising material prices.

DfD facilitates the creation of modular and standardized designs. This modularity allows for easier component replacement and repair, minimizing downtime and reducing the need for extensive repairs. It also enables the creation of a robust supply chain for replacement parts, ensuring availability and reducing the cost of maintaining a large inventory of spare parts. The ability to quickly and easily disassemble a product also contributes to a more efficient repair process, leading to cost savings in the long run by avoiding costly replacements. This economic advantage extends beyond the initial product lifecycle, positively impacting the entire supply chain and promoting circular economy principles.

Environmental Advantages of DfD

DfD plays a crucial role in promoting sustainability by minimizing environmental impact. By designing products for easy disassembly, companies can significantly increase the rate of material recovery and recycling. This reduces the demand for virgin materials, conserving natural resources and lowering our reliance on finite reserves. DfD also minimizes waste generation by enabling the reuse and repurposing of components, reducing the amount of waste sent to landfills. The focus on durability and repairability inherent in DfD practices leads to products with a longer lifespan, reducing the overall number of products manufactured and disposed of over time, making a significant impact on our planet.

The environmental benefits extend beyond the product itself. DfD encourages the design of products that are easier to transport and handle during the disassembly process. This can lead to reduced energy consumption and emissions throughout the entire product lifecycle, from manufacturing to disposal. By optimizing the use of materials and minimizing waste, DfD contributes to a more sustainable approach to product design, fostering a circular economy model that prioritizes resource efficiency and minimizes environmental harm. Reduced energy consumption during manufacturing and disassembly is a further positive environmental outcome.

DfD and Circular Economy Integration

The integration of DfD into the circular economy model is increasingly crucial for achieving sustainable development goals. By designing products for disassembly and reuse, companies can contribute to a more closed-loop system, where materials are continuously reused and recycled. This approach fosters a shift away from a linear take-make-dispose model to a circular model that prioritizes resource efficiency and minimizes environmental impact. DfD allows for the creation of products that are designed for multiple lifecycles, extending their useful life and reducing the need for new products, thus reducing the environmental footprint of products.

DfD principles directly align with the principles of the circular economy by promoting the reuse, repair, and recycling of materials. This approach maximizes the value of materials throughout their entire lifecycle and reduces the reliance on finite resources. DfD is essential for achieving a truly sustainable future, encouraging a transition towards a circular economy where resources are utilized more effectively and environmental impact is minimized. By incorporating DfD principles, companies and consumers can actively participate in a more sustainable future.