From Concept to Consumer: Designing for Sustainability

Material Selection Considerations

Choosing the right material for a project is crucial for its success, durability, and cost-effectiveness. Material selection involves a careful evaluation of various factors, including mechanical properties, chemical resistance, thermal stability, and environmental impact. This initial step often dictates the overall performance and lifespan of the final product.

Mechanical Properties

Understanding the mechanical properties of potential materials is paramount. This includes factors like tensile strength, yield strength, hardness, and elasticity. These properties directly influence the material's ability to withstand stress and strain during use. For example, a material with high tensile strength is better suited for applications requiring resistance to pulling forces.

Chemical Resistance

The chemical environment in which the material will be used is a significant consideration. Materials that exhibit high resistance to corrosion, degradation, or chemical reactions are preferred for applications involving harsh or reactive substances. The selection of a material with appropriate chemical resistance is essential to prevent premature failure and maintain product integrity over time.

Thermal Stability

The temperature range in which the material will operate plays a crucial role. Some materials exhibit superior performance at high temperatures, while others are better suited for low-temperature environments. Understanding the material's thermal stability is crucial to ensure consistent performance under various temperature fluctuations and prevent structural damage.

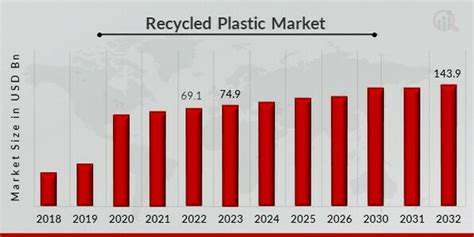

Cost and Availability

The cost of the material and its availability in the desired quantity and quality are practical considerations. Balancing cost-effectiveness with performance is an important aspect of material selection. Additionally, the ease of procuring and processing the material should be taken into account. Sourcing materials efficiently can save considerable time and resources.

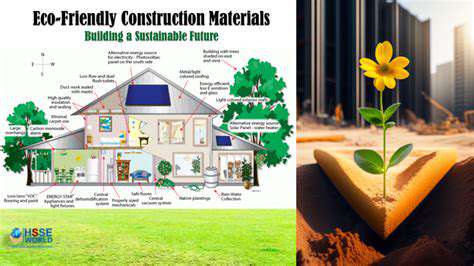

Environmental Impact

Sustainability is increasingly important in material selection. Consideration must be given to the environmental impact of the material throughout its lifecycle, from extraction and processing to disposal. Choosing environmentally friendly materials can reduce the overall carbon footprint of a project and contribute to a more sustainable future. Materials with a lower environmental impact are often preferred.

Manufacturing Process Compatibility

The chosen material must be compatible with the manufacturing processes used to create the final product. Different materials require different fabrication techniques and equipment, which can influence the overall cost and feasibility of the project. Compatibility between the material and the manufacturing process is crucial for achieving the desired quality and efficiency.

Predictive analytics, a powerful subset of data science, leverages historical data and statistical algorithms to forecast future trends and outcomes in the market. This process involves identifying patterns and relationships within the data to build models that can accurately predict future market behavior. Various techniques are employed, including machine learning algorithms like regression, classification, and clustering, allowing businesses to anticipate market shifts and proactively adjust strategies. By understanding the potential impacts of these shifts, businesses can make more informed decisions and improve their overall market performance.

Circular Economy Principles: Designing for End-of-Life Considerations

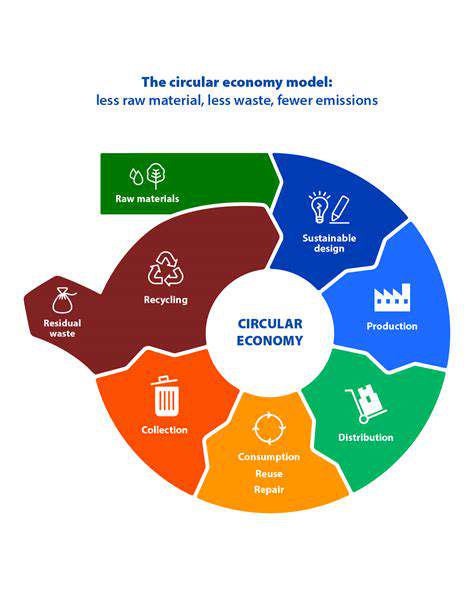

Circular Economy Principles: Design

The circular economy model fundamentally shifts the linear take-make-dispose approach to design. It emphasizes the importance of designing products and processes to be sustainable and reusable, minimizing waste and maximizing resource efficiency. This design-centric approach considers the entire lifecycle of a product, from raw material extraction to end-of-life management, ensuring that materials are kept in use for as long as possible and that waste is minimized at every stage.

A key aspect of this design is the concept of durability and repairability. Products are designed with longevity in mind, using high-quality materials and robust construction to extend their lifespan. This approach also encourages the development of repair and refurbishment services, allowing products to be reused and remanufactured rather than discarded.

Circular Economy Principles: Reuse

The circular economy prioritizes reuse over disposal. This principle extends beyond simply reusing existing products or materials. It also involves designing for reuse by creating products with modular components that can be easily disassembled and repurposed. This approach promotes a shift from a throwaway mentality to one where resources are valued and utilized effectively throughout their lifecycle.

By embracing reuse, we can significantly reduce the demand for new resources, lessen our environmental impact, and stimulate economic activity in repair and refurbishment sectors. This involves fostering a culture of reuse and repurposing, encouraging innovative solutions for extending the life of products and materials.

Circular Economy Principles: Resource Management

A critical component of the circular economy is efficient resource management. This involves minimizing resource consumption through the optimization of processes and the use of renewable resources whenever possible. It also necessitates a shift towards a system that prioritizes the recovery and reuse of materials at the end of a product's lifecycle. This includes implementing effective waste management strategies and developing innovative technologies for material recovery and recycling.

Effective resource management is crucial for minimizing waste and maximizing the value of materials throughout their lifecycle. It demands a proactive approach to waste prevention and the development of closed-loop systems where materials are continuously recycled and reused.

Circular Economy Principles: Collaboration

The success of a circular economy relies heavily on collaboration among various stakeholders, including businesses, governments, and consumers. This collaborative approach fosters innovation and the development of new solutions. By working together, stakeholders can share knowledge, resources, and best practices to accelerate the transition towards a circular economy. This includes establishing partnerships and developing shared strategies for resource management and waste reduction.

Collaboration is essential for the development and implementation of policies and initiatives that support the circular economy. This encompasses creating incentives for businesses to adopt circular practices, promoting public awareness, and establishing clear regulations to ensure responsible resource management.