From Farm to Fashion: Sustainable Supply Chain Practices

From the Humble Seed

The journey of creating a garment begins with a tiny seed, a quiet promise of potential waiting to blossom. These unassuming beginnings hold the genetic instructions for the fibers that will one day drape our bodies. Farmers carefully select and plant these seeds, knowing they represent the first stitch in nature's textile tapestry.

This foundational stage demonstrates why ecological farming matters more than ever. When growers choose organic seeds and regenerative methods, they're not just planting crops - they're cultivating the future of fashion.

Cultivating the Fiber

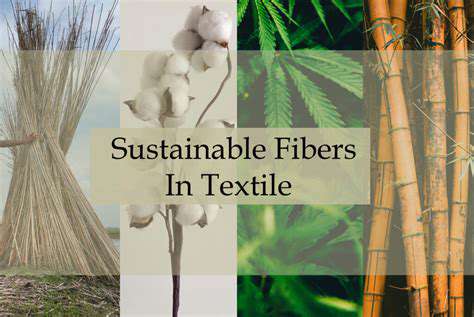

Watching plants transform sunlight into textile fibers remains one of nature's quiet miracles. Cotton plants stretch toward the sky, their fluffy bolls swelling with promise. Flax stalks dance in the wind, their fibrous stems hiding linen's potential. The relationship between farmer and field during these growing months directly shapes the fabric's eventual character. Soil health, water management, and pest control all leave their mark on the fibers' DNA.

Harvesting the Bounty

Harvest season brings both celebration and careful labor. Workers gently gather cotton by hand or machine, while flax stalks undergo retting to loosen their valuable fibers. How these crops are handled at harvest determines whether months of careful cultivation pay off. Bruised cotton fibers or poorly retted flax can compromise quality before processing even begins.

Preparing for Transformation

Before fibers can spin into yarn, they undergo meticulous preparation. Cotton gets ginned to remove seeds, while flax undergoes scutching to separate linen fibers from woody stalks. Skilled workers sort and align each strand by length and quality. This behind-the-scenes work doesn't make fashion headlines, but it makes all the difference in fabric quality.

The Alchemy of Spinning

Spinning transforms disjointed fibers into continuous yarn through twist and tension. Traditional spinning wheels whisper ancient secrets while modern machines hum with precision. The spinner's choices here - twist tightness, fiber blending - become the fabric's hidden language of drape and durability. This is where plant potential becomes textile reality.

Weaving Connections

Looms click and clatter as they transform yarn into fabric, each pass of the shuttle writing another line in the textile's story. Knitting needles dance, looping yarn into elastic fabrics that stretch with our lives. The choice between weaving and knitting isn't just technical - it's philosophical, determining how fabric will move and age with its wearer.

The Final Stitch

Cutters, sewers, and finishers transform flat fabric into dimensional garments. Seamstresses match patterns with precision while quality inspectors examine every stitch. These final human touches remind us that even in our automated world, clothing remains profoundly personal - the meeting point of nature's materials and human care.

Transparency and Traceability: Mapping the Supply Chain

Why Maps Matter

Our supply chain map makes complex systems visible, turning abstract processes into understandable pathways. Like X-rays for fashion's skeleton, these visualizations reveal both strengths and stress points in how materials move from field to wardrobe. What gets measured gets managed - and what gets visualized gets improved.

Interactive Insights

Zoom into any node on our digital map and watch the supply chain come alive. Trace organic cotton from Indian farms to Italian mills to Canadian sewers. This interactivity transforms passive observers into active participants in sustainability efforts. Real-time updates mean the map breathes with the rhythm of global production.

Data with Integrity

Blockchain verification, third-party audits, and supplier certifications create multiple layers of accountability. We treat data like organic matter - it must be traceable to its roots to be trusted. Each validation step reinforces the map's reliability as a decision-making tool for conscientious brands and consumers alike.