The Challenges of Ethical Sourcing in Multi Tier Supply Chains

Transparency in Supply Chains: A Critical Need

Supply chain visibility has emerged as a business imperative in our interconnected economy. Consumer trust increasingly hinges on product origin stories, with detailed sourcing information becoming a competitive differentiator. This paradigm shift reflects growing public awareness about consumption impacts.

Modern shoppers actively investigate production ethics, seeking assurance about worker welfare, environmental practices, and material sustainability before purchasing decisions.

Traceability: Enhancing Supply Chain Efficiency

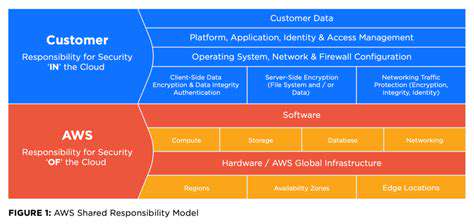

Comprehensive tracking systems now enable item-level visibility from raw materials to retail shelves. This granular oversight allows near-instantaneous issue detection, whether addressing quality anomalies or ethical breaches. Such responsive capabilities minimize operational disruptions while reinforcing quality assurance protocols.

Sophisticated traceability solutions create digital threads across supply networks, enabling targeted interventions and continuous process improvements.

Benefits of Enhanced Transparency

Supply chain openness delivers measurable business advantages. The reputational capital gained through transparency directly translates to customer retention and market share growth. Equally important, transparent operations foster more collaborative and resilient supplier relationships.

Operational efficiencies emerge naturally from transparent systems, reducing waste, accelerating problem-solving, and future-proofing against regulatory changes.

Challenges in Achieving Transparency

Implementation barriers remain significant despite clear benefits. Integrating disparate data systems across global partners requires substantial technical coordination. The exponential growth of supply chain data presents both opportunities and analytical complexities.

Divergent international standards compound these challenges, necessitating adaptable frameworks that meet varied compliance requirements while maintaining core ethical standards.

Technological Solutions for Transparency

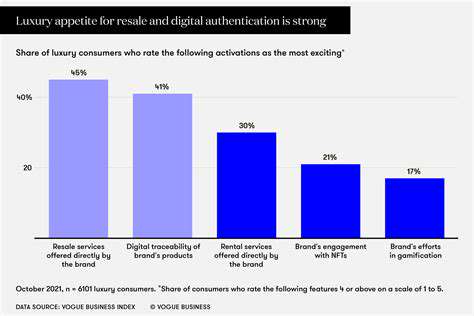

Emerging technologies are revolutionizing supply chain visibility. Distributed ledger systems and IoT sensors enable unprecedented real-time monitoring capabilities. These innovations create immutable audit trails that enhance accountability while streamlining operations.

Ethical Considerations and Social Responsibility

Transparency initiatives must align with broader ethical commitments. Responsible companies ensure visibility systems also monitor labor conditions, environmental impacts, and community effects. Authentic ethical sourcing strengthens brand integrity and cultivates deeper consumer connections.

Proactive transparency allows companies to identify and rectify supply chain issues before they escalate, contributing to more sustainable global trade systems.

Measuring the Impact of Transparency Initiatives

Effective transparency programs establish clear success metrics tracking stakeholder trust, supply chain resilience, and ethical compliance. Regular impact assessments ensure continuous improvement and adaptation to evolving best practices.

Benchmarking against industry standards helps contextualize progress while identifying opportunities for leadership in supply chain responsibility.

Environmental Sustainability: Balancing Production and Planet

Minimizing Environmental Impact in Production

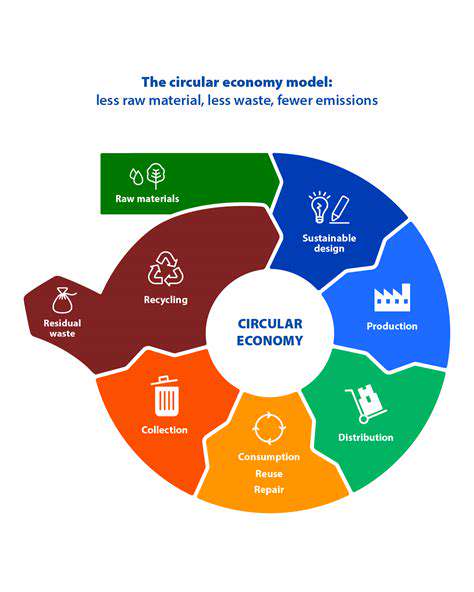

Sustainable manufacturing has transitioned from optional to essential in responsible business operations. Leading companies now implement cradle-to-grave environmental strategies encompassing material sourcing, production processes, distribution logistics, and product afterlife. This comprehensive approach integrates circular economy principles, renewable energy adoption, and waste minimization tactics. The most progressive organizations view sustainability investments not as costs but as future-proofing measures that drive long-term competitiveness.

While adopting green technologies requires upfront capital, the operational efficiencies and brand equity gains typically deliver compelling ROI over time.

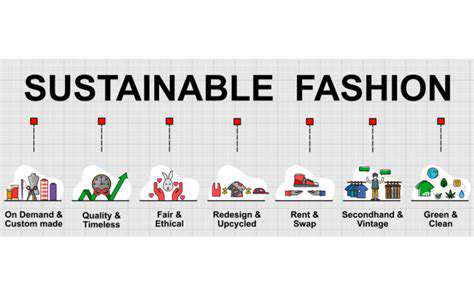

The Role of Sustainable Materials

Material selection represents a pivotal sustainability leverage point. Innovators now prioritize recycled feedstocks, rapidly renewable resources, and bio-based alternatives that minimize ecological damage. Advanced material science continues expanding possibilities, with breakthroughs in biodegradable composites and low-impact manufacturing processes reshaping production paradigms.

Waste Reduction and Management Strategies

Cutting-edge waste management moves beyond basic recycling to embrace industrial symbiosis models where one process's byproducts become another's raw materials. Progressive manufacturers design products for disassembly and reuse, while investing in advanced sorting and reprocessing infrastructure that maximizes material recovery rates.

Energy Efficiency and Renewable Resources

The transition to renewable energy represents both environmental imperative and strategic advantage. Smart factories now combine energy-efficient equipment with onsite solar/wind generation and sophisticated energy management systems. These integrated approaches dramatically reduce carbon footprints while insulating operations from energy price volatility.

Economic Considerations of Sustainable Production

Sustainability economics have matured beyond simple cost-benefit analyses. Forward-looking accounting now quantifies the full value of risk mitigation, brand enhancement, and operational resilience gained through green initiatives. The most sophisticated models incorporate externalized environmental costs, revealing the true economic benefits of sustainable practices.

Transparency and Accountability in Supply Chains

Environmental responsibility extends beyond factory walls to encompass entire value chains. Industry leaders implement rigorous supplier sustainability assessments, collaborative improvement programs, and transparent reporting mechanisms. This ecosystems approach ensures environmental standards permeate every production tier while fostering innovation through supplier partnerships.