The Impact of Chemical Exposure on Garment Workers: Health and Safety: New Research

Textile Dyeing: A Sea of Chemicals

Vibrant clothing colors often conceal a troubling reality. Textile dyeing processes frequently utilize hazardous substances like azo dyes and heavy metals that can permeate fabrics. These chemical residues pose measurable health threats to both garment workers and end consumers, making comprehensive safety protocols essential. The variability in chemical concentrations across different dyes and fabrics necessitates rigorous testing to ensure product safety.

Finishing Agents and Their Potential Risks

While finishing treatments enhance fabric qualities like wrinkle resistance, they often contain problematic compounds. Formaldehyde, despite its effectiveness, demonstrates clear carcinogenic properties in multiple studies. The cumulative health impact of prolonged exposure to these substances remains a critical area of scientific investigation.

The Impact on Worker Health

Textile manufacturing employees face daily exposure to chemical cocktails during production stages. Documented health outcomes include chronic respiratory conditions, persistent dermatitis, and systemic organ damage. Effective mitigation requires comprehensive safety measures including advanced ventilation systems and mandatory protective equipment, coupled with regular medical monitoring for at-risk workers.

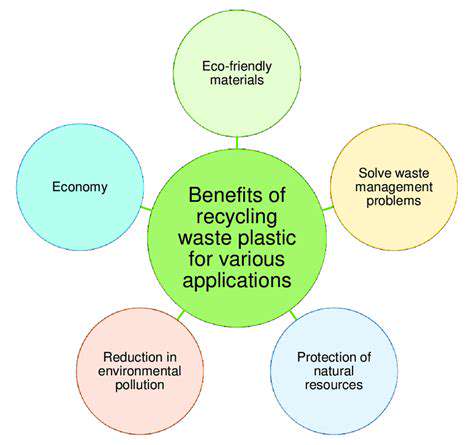

Environmental Concerns: Pollution from Textile Waste

Factory effluent containing synthetic dyes and processing chemicals creates persistent environmental contamination. These pollutants disrupt aquatic ecosystems and may enter human food chains through bioaccumulation. Modern wastewater treatment solutions offer some remediation potential, but their implementation remains inconsistent globally.

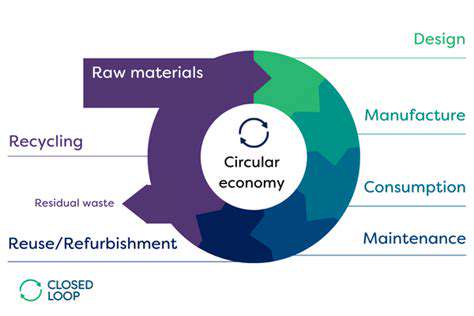

Sustainable Alternatives: Moving Towards Eco-Friendly Practices

Innovative approaches are emerging, including plant-based colorants and biodegradable fabric treatments. While these alternatives currently represent a small market segment, their adoption signals a positive industry shift toward reduced ecological impact.

Consumer Awareness and Responsible Consumption

Informed purchasing decisions can drive industry change. Consumers prioritizing sustainably produced garments create market incentives for chemical use reduction. Transparent labeling systems help buyers identify truly eco-conscious products amidst prevalent greenwashing tactics.

Regulation and Enforcement: A Crucial Role in Safety

Effective governance requires both robust chemical use policies and consistent compliance verification. Unannounced facility inspections and stringent penalties for violations prove most effective in ensuring worker protections and environmental standards.

The Spectrum of Chemical Hazards in the Garment Industry

Chemical Dyes and Pigments

The apparel sector's dependence on synthetic colorants creates numerous exposure risks. Allergic reactions and respiratory complications occur disproportionately among dye handlers, with risk levels varying by chemical composition. Mandatory safety training and proper labeling represent basic protective measures that many facilities still neglect.

Finishing Agents and Textiles Treatments

Fabric enhancement chemicals frequently contain volatile compounds that affect both human health and atmospheric quality. Substituting traditional formulations with low-VOC alternatives significantly reduces these dual impacts.

Preservatives and Antimicrobial Agents

While preventing microbial growth is necessary, some common preservatives demonstrate concerning toxicity profiles. Safer alternatives exist but often at higher production costs that discourage widespread adoption.

Textile Adhesives and Glues

Many garment assembly adhesives release harmful fumes during application. Proper respiratory protection and workspace ventilation dramatically decrease associated health risks for production staff.

Solvents and Cleaners

Industrial cleaning agents present acute exposure hazards requiring strict handling protocols. Facility managers must balance cleaning efficacy with worker safety considerations when selecting chemical products.

Heavy Metals in Fabric Finishes

Metallic fabric treatments pose particularly persistent environmental threats due to their non-degradable nature. Regulatory limits on heavy metal concentrations in textiles have proven effective where properly enforced.

Historical evidence shows that natural remedies have provided health solutions across cultures for centuries. Contemporary research continues to validate many traditional botanical applications, particularly in veterinary medicine where gentler interventions are often preferable.