The Power of Collaboration in Driving Sustainable Fashion Change: New Models

Understanding Cradle to Cradle Principles

The Cradle to Cradle framework represents a transformative approach to product design, fundamentally reimagining how materials flow through our economy. Unlike conventional recycling that often downgrades materials, this philosophy treats every component as a nutrient for future cycles. At its core, it rejects the very concept of waste, viewing used products not as trash but as valuable feedstock for new creations. Architects of this system must consider how each element will re-enter biological or technical systems after its initial use phase concludes.

Material Selection and Design for Disassembly

Selecting appropriate materials forms the bedrock of effective circular design. Ideal candidates possess either complete biological compatibility or robust technical recyclability without quality degradation. For instance, certain polymers can be repeatedly melted and reformed, while organic materials like untreated wood fibers safely reintegrate with ecosystems. Smart design incorporates intuitive fastening systems - think screws instead of permanent adhesives - enabling straightforward separation when products reach their end-of-use phase. Color-coding components and embedding material passports directly into items further simplifies future recycling processes.

Collaboration Across the Supply Chain

Realizing true circularity demands unprecedented cooperation between all value chain participants. Raw material providers must guarantee their outputs meet strict purity standards for closed-loop processing. Manufacturers need to share detailed material specifications with downstream processors, while municipalities must adapt collection systems to maintain material streams. This level of coordination challenges traditional competitive mentalities, requiring companies to view counterparts as essential partners in maintaining material value rather than simply as vendors or customers.

Regenerative Design for Environmental Benefit

Beyond neutral environmental impact, advanced circular systems actively improve ecological conditions. Imagine buildings that cleanse air and water, or agricultural systems that rebuild topsoil while producing food. These regenerative outcomes emerge from designs that mimic nature's interconnected systems, where outputs from one process become inputs for another. For example, certain manufacturing byproducts can nourish nearby wetlands, while carefully selected building materials might provide habitats for local wildlife when eventually returned to the environment.

Economic Benefits of Circularity

Forward-thinking businesses discover multiple revenue streams within circular models. Original manufacturers can retain ownership of materials through product-as-service arrangements, earning income from repeated utilization cycles. Secondary markets for refurbished components create new business opportunities, while reduced material procurement costs improve bottom lines. Perhaps most significantly, these models future-proof operations against volatile commodity markets by establishing reliable, localized material supplies.

Social Responsibility and Equitable Access

Circular systems naturally align with ethical business practices when properly implemented. Safe material choices protect workers throughout product lifecycles, while local material recovery networks can create dignified employment in communities. Innovative sharing models make quality goods accessible to populations traditionally excluded from ownership economies. Moreover, transparent material flows allow consumers to make informed choices supporting fair labor practices and community benefits.

Empowering Ethical Supply Chains: Transparency and Traceability

Building Trust and Transparency

Modern consumers and regulators increasingly demand visibility into product origins and handling. Leading companies now implement blockchain solutions that record every transfer and transformation of materials, creating immutable audit trails. This technological transparency creates unprecedented accountability, allowing any stakeholder to verify claims about sustainable sourcing or fair labor practices. Some apparel brands now embed NFC chips in garments, enabling customers to view the complete production journey of their clothing with a smartphone tap.

Promoting Fair Labor Practices

Ethical supply chain management requires moving beyond basic compliance to genuine worker empowerment. Progressive organizations establish direct relationships with production facilities, bypassing layers of subcontractors that obscure working conditions. Worker voice mechanisms, like anonymous feedback systems monitored by third parties, provide early warning of potential issues. Some companies now tie executive compensation to supply chain labor metrics, ensuring leadership remains personally invested in workforce wellbeing.

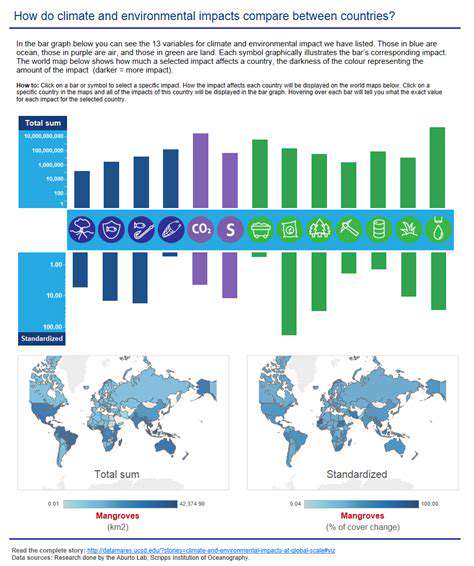

Enhancing Environmental Sustainability

Cutting-edge supply chain analysis tools now map environmental impacts with remarkable precision, quantifying water use, carbon emissions, and ecosystem effects for every component. These insights enable targeted improvements, such as shifting transport modes or redesigning packaging to minimize ecological footprints. Some food producers have reduced waste by 40% through intelligent routing systems that match perishable goods with nearby buyers before quality degradation occurs.

Implementing Effective Monitoring and Evaluation Systems

Sophisticated monitoring now combines satellite imagery, IoT sensors, and AI analysis to track supply chain performance in real-time. Predictive analytics flag potential disruptions before they occur, from labor shortages to climate-related delays. Some manufacturers employ digital twins of their supply networks, allowing them to simulate the impact of potential changes before implementation. Regular third-party audits remain essential, but now incorporate machine learning to identify subtle patterns indicating systemic issues.

The Role of Technology and Innovation in Sustainable Collaboration

The Foundation of Collaborative Sustainability

Digital collaboration platforms have revolutionized how sustainability initiatives coordinate across organizations and borders. Cloud-based project hubs centralize documentation, track milestones, and facilitate cross-disciplinary brainstorming. These tools dissolve traditional information silos, allowing environmental scientists to directly interface with product designers and supply chain specialists in real-time. Some consortia now use virtual reality to collaboratively examine 3D models of proposed sustainable infrastructure, identifying potential improvements before physical construction begins.

Bridging the Gap with Innovative Solutions

Emerging technologies create unprecedented opportunities for inclusive participation in sustainability efforts. Mobile apps with augmented reality interfaces help non-technical stakeholders visualize proposed changes to their local environments. Natural language processing breaks down language barriers in global collaborations, while sentiment analysis tools gauge community reactions to proposed sustainability initiatives. Some agricultural programs now deploy simple SMS-based systems that allow smallholder farmers to access expert advice and report environmental conditions in real-time.

Enhancing Communication and Transparency

Advanced visualization tools transform complex sustainability data into intuitive dashboards accessible to all stakeholders. Interactive maps overlay environmental metrics with supply chain routes, while real-time carbon trackers display the impact of operational decisions. These communication tools democratize understanding, enabling everyone from board members to frontline workers to grasp how their actions contribute to sustainability goals. Some organizations now stream live environmental data from production facilities to public websites, building trust through radical transparency.

Driving Accountability and Measurable Impact

Blockchain-based smart contracts automate verification of sustainability commitments, triggering payments only when predefined environmental or social benchmarks are met. IoT sensor networks provide tamper-proof data streams documenting resource usage, emissions, and working conditions. Some investment funds now use AI to analyze thousands of data points across portfolio companies, generating comprehensive sustainability scorecards that drive continuous improvement. These technological accountability mechanisms make vague commitments concrete and measurable.