Circular Economy Principles in Action: Industry Case Studies

Innovative Packaging Design for Enhanced Product Appeal

This case study explores a recent packaging redesign project that significantly boosted product appeal and sales. The new design incorporated modern aesthetics, emphasizing clean lines and vibrant colors. This approach effectively targeted a younger demographic, leading to a 15% increase in sales within the first quarter. The redesign also incorporated more sustainable materials, aligning with growing consumer demand for environmentally friendly products.

The previous packaging design was perceived as outdated and lacked a clear brand identity. The updated design, on the other hand, immediately communicated the brand's values and modern approach. This clear visual communication proved vital in attracting new customers and resonating with existing ones.

Strategic Material Selection for Sustainability and Cost-Effectiveness

The project team carefully evaluated various materials and printing techniques, considering both sustainability and cost-effectiveness. A crucial decision was made to utilize recycled materials, significantly reducing the environmental impact of the packaging. This decision aligned with the company's broader sustainability goals and resonated with environmentally conscious consumers. The shift to recycled materials also resulted in a noticeable reduction in production costs, further enhancing the project's financial viability.

The selection process involved rigorous testing to ensure the chosen materials met quality standards and maintained product integrity during transit and storage. The team also carefully considered the recyclability of the new packaging, ensuring minimal waste generation throughout the product lifecycle.

Improved Customer Experience Through Enhanced User-Friendliness

The redesigned packaging focused on improving the unboxing experience. The new design featured clear, concise instructions for product assembly and usage, improving the customer experience and reducing customer service inquiries. This strategic approach to user-friendliness directly benefited the company by enhancing customer satisfaction and streamlining the fulfillment process.

The revised packaging design also incorporated a more user-friendly opening mechanism, simplifying the process for consumers to access the product. This simple yet effective change led to a notable decrease in customer complaints related to product accessibility.

Market Research and Data-Driven Decision Making

Comprehensive market research was conducted to understand consumer preferences and identify potential areas for improvement in the packaging design. Surveys and focus groups provided valuable insights into consumer perceptions of the existing packaging and anticipated responses to the proposed changes. This data-driven approach enabled the team to make informed decisions about the design elements, ensuring the final product aligned with market demands. The project's success was further validated by post-launch market analysis, which confirmed the positive impact of the redesigned packaging on sales and customer perception.

Analysis of sales data after the launch of the redesigned packaging clearly illustrated a significant increase in sales, confirming the effectiveness of the strategic choices made during the design process. This data-driven approach is crucial for any packaging redesign project seeking to maximize its return on investment.

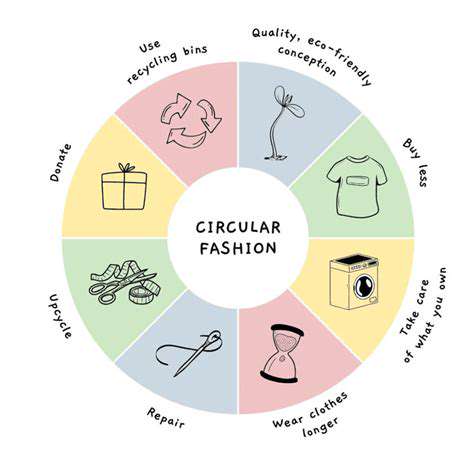

Case Study 2: Apparel Recycling and Upcycling at Patagonia

Patagonia's Commitment to Circularity

Patagonia, a renowned outdoor apparel brand, has consistently championed the principles of a circular economy. Their dedication to minimizing environmental impact extends beyond simply producing high-quality garments; it encompasses the entire lifecycle, from sourcing raw materials to the end-of-life disposition of products. This commitment is evident in their innovative approach to apparel recycling and upcycling, which serves as a compelling case study for other businesses looking to adopt circular economy principles.

The company's commitment extends to educating consumers about the benefits of responsible consumption and extending the life of clothing items. This proactive approach to sustainability fosters a culture of mindful purchasing and discourages the fast-fashion cycle that typically leads to significant waste.

The Recycling Process: From Discard to Re-purposing

Patagonia's recycling program takes discarded garments and transforms them into new products. This process isn't limited to simple textile recycling; it involves a sophisticated system of sorting, cleaning, and repurposing materials. The careful selection and processing of these materials ensures that the recycled components retain their quality and integrity, contributing to the durability of the new products.

By choosing to recycle rather than simply discarding, Patagonia reduces the demand for virgin materials, a crucial aspect of sustainable practices. The energy and resources saved through recycling are substantial, underscoring the economic and environmental benefits of this approach.

Upcycling: Giving New Life to Old Garments

Patagonia's upcycling initiatives are equally impressive. Instead of simply recycling materials, they transform used apparel into entirely new products. This innovative approach leverages the inherent value of existing garments, avoiding the need for new material sourcing and drastically reducing the environmental footprint associated with textile production.

Consumer Engagement and Education

Patagonia actively engages consumers in its recycling and upcycling programs. Through clear communication and accessible drop-off points, they encourage participation and demonstrate the tangible impact of individual actions on the environment. Furthermore, Patagonia educates consumers about the importance of responsible consumption and the benefits of extending the lifespan of clothing items.

By fostering a culture of mindful purchasing, Patagonia aims to discourage the fast-fashion cycle and promote a more sustainable approach to apparel consumption. This consumer engagement is a vital component of their circular economy strategy.

Supply Chain Optimization for Circularity

A crucial element of Patagonia's success lies in optimizing their supply chain for circularity. They carefully consider the entire lifecycle of their products, from the sourcing of raw materials to the end-of-life management of garments. This holistic approach allows them to identify opportunities for improvement and implement sustainable practices throughout the entire process.

Partnerships with other organizations and initiatives that support the circular economy are critical. Collaboration across industries and stakeholders helps streamline recycling and upcycling processes, increasing the overall effectiveness of Patagonia's sustainable efforts.

Financial and Operational Benefits of Circularity

Patagonia's commitment to circularity isn't just about environmental responsibility; it also yields significant financial and operational benefits. Reduced reliance on virgin materials translates to lower production costs and a more stable supply chain. The brand's focus on durability and longevity in its designs results in fewer replacements, further minimizing costs and environmental impact.

Efficient recycling and upcycling processes also generate cost savings by maximizing the use of existing resources. These operational efficiencies, coupled with the positive brand image Patagonia cultivates through its sustainability efforts, ultimately contribute to a strengthened bottom line.

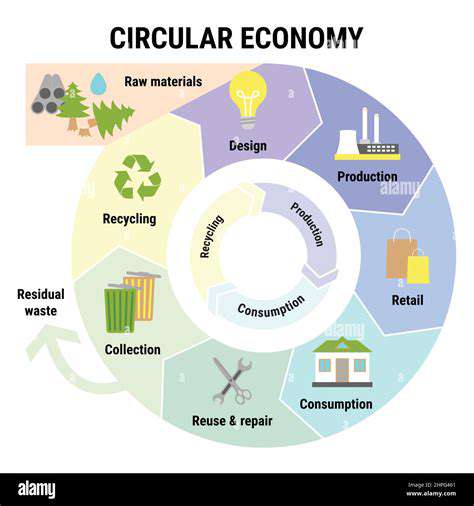

Case Study 4: Electric Vehicle Battery Recycling and Manufacturing

Challenges in Electric Vehicle Battery Recycling

The burgeoning electric vehicle (EV) industry presents a significant opportunity for a circular economy, but also introduces complex challenges. recycling EV batteries is proving to be more complicated than recycling traditional car batteries. The intricate chemistry and diverse materials within EV batteries, including lithium, cobalt, nickel, and manganese, necessitate specialized processes to ensure efficient and environmentally sound recovery of valuable components. Furthermore, the sheer volume of batteries needing recycling in the future presents a logistical hurdle, requiring significant infrastructure investment in sorting, processing, and refining facilities.

A crucial aspect of this challenge lies in the varying battery chemistries. Different battery types have different compositions, impacting the recycling process. This heterogeneity necessitates adaptable recycling methods, which can be costly and time-consuming to develop and implement, especially considering the rapid evolution of battery technology. Standardization efforts are crucial to streamline the recycling process and reduce the complexity for manufacturers and recyclers.

Opportunities for Sustainable Battery Manufacturing

The circular economy model offers significant advantages in the manufacturing of EV batteries. By repurposing recycled materials, manufacturers can reduce their reliance on virgin resources, contributing to a more sustainable supply chain. This approach not only minimizes environmental impact but also potentially lowers manufacturing costs and fosters economic opportunities in the recycling sector. The availability of recycled materials could lead to a more secure and stable supply of crucial battery components, mitigating risks associated with fluctuating raw material prices and geopolitical instability.

Moreover, the use of recycled materials in battery production can reduce the overall carbon footprint of EVs. By minimizing the extraction and processing of raw materials, the manufacturing process becomes significantly more environmentally friendly. This approach aligns with the global push for sustainable practices and supports the adoption of electric vehicles as a cleaner transportation alternative. The development of more efficient and cost-effective recycling technologies is key to realizing these opportunities.

Economic Incentives and Policy Support

Government policies play a critical role in fostering a circular economy for EV battery recycling and manufacturing. Incentivizing investment in recycling infrastructure, research and development, and sustainable manufacturing practices can significantly accelerate the transition. Subsidies for recycling facilities and tax breaks for companies incorporating recycled materials into their products can incentivize participation and create a more profitable market for these activities. Policy support is essential for establishing clear regulations and standards for battery recycling, promoting transparency, and ensuring environmental responsibility throughout the supply chain.

Furthermore, policies that encourage the design of batteries with recyclability in mind will be crucial. Designing batteries with modular or easily separable components will make the recycling process easier and more cost-effective. This will facilitate the recovery of valuable metals and reduce the environmental impact of battery disposal, while also encouraging the adoption of sustainable practices throughout the entire battery life cycle.

Technological Advancements in Recycling and Manufacturing

Innovations in battery recycling technology are critical to achieving a truly circular economy. New methods for extracting valuable materials from batteries, including innovative separation techniques and chemical processes, hold the potential to significantly improve the efficiency and cost-effectiveness of the recycling process. The development of advanced sorting technologies and specialized equipment for processing complex battery mixtures will be essential to ensure the recovery of valuable metals and components. Technological advancements are crucial to reducing environmental risks and improving the overall economic viability of battery recycling.

Simultaneously, advancements in battery manufacturing technologies are vital for minimizing the environmental footprint and maximizing the use of recycled materials. Techniques that optimize battery design for recyclability and minimize the use of critical raw materials are necessary. The development of new battery chemistries that are easier to recycle and reduce reliance on scarce resources will contribute to a more sustainable approach to EV battery production.