Sustainable Footwear from Recycled Plastics: New Designs

Sustainable Materials: A Revolution in Footwear

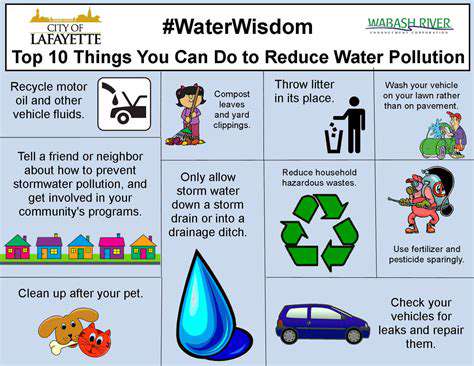

The future of sustainable footwear hinges significantly on the adoption of innovative and eco-friendly materials. Traditional leather production often involves significant environmental impact, including deforestation and water pollution. Alternatives such as plant-based leathers, mushroom leather, and recycled materials are gaining traction, offering a pathway towards minimizing the footprint of footwear manufacturing. These materials often boast comparable performance characteristics to traditional leather, providing durability and aesthetic appeal, while simultaneously reducing the reliance on unsustainable resources.

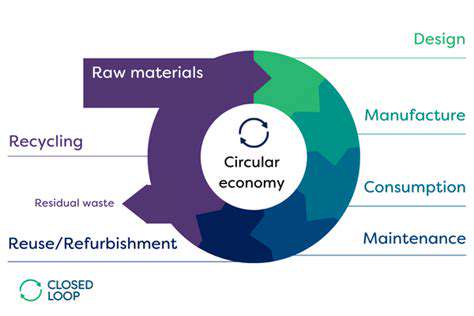

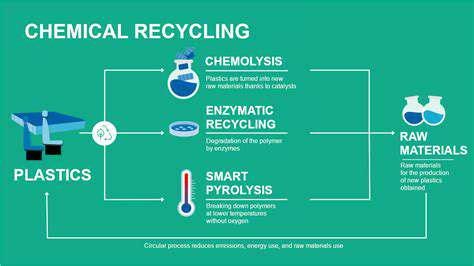

The use of recycled plastics and rubber in footwear production is also a key element of this revolution. By repurposing existing waste materials, the industry can significantly cut down on landfill waste and reduce the need for virgin resources. This process not only reduces the environmental impact but also promotes a circular economy model, fostering a more sustainable approach to manufacturing. These eco-friendly materials are becoming increasingly available and affordable, making them a viable option for both consumers and manufacturers.

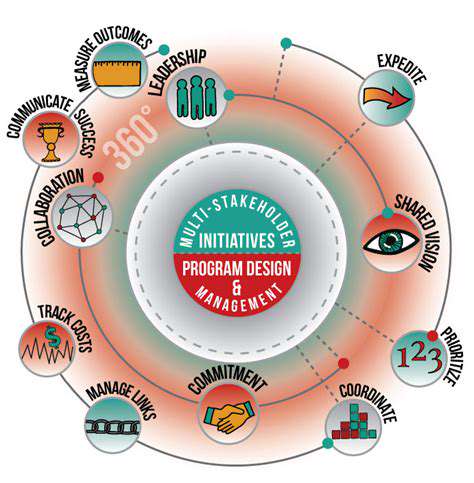

Ethical Production Practices: Fair Labor and Transparency

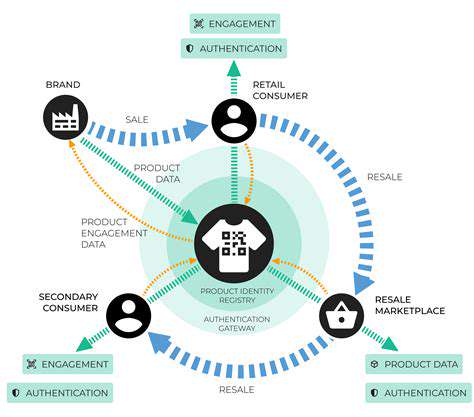

Sustainable footwear isn't just about the materials; it's also deeply intertwined with ethical production practices. Transparency in the supply chain is paramount, allowing consumers to trace the journey of their footwear from raw materials to finished product. This transparency fosters trust and accountability, ensuring that the producers are upholding fair labor standards and not exploiting workers in the process.

Promoting fair wages, safe working conditions, and respect for human rights within the footwear industry is crucial. This includes providing workers with benefits, such as health insurance and paid time off, and ensuring a safe and healthy working environment. Consumers are increasingly demanding ethical production practices, and companies that prioritize these values are likely to see greater success in the long run.

Technological Advancements: Innovation in Design and Manufacturing

Technological advancements play a pivotal role in driving the future of sustainable footwear. 3D printing, for example, allows for the creation of highly customized and intricate designs, potentially reducing waste associated with traditional manufacturing methods. This innovative approach enables the creation of unique and personalized footwear that caters to individual needs and preferences.

Furthermore, advancements in bio-engineering and material science are leading to the development of more sustainable and durable footwear. These advancements hold the potential to dramatically reduce the environmental impact of the footwear industry. Innovation in manufacturing processes, such as reducing water usage in the production of textiles, and minimizing energy consumption in factories, are all part of the ongoing quest for greater sustainability.

Circular Economy Models: Extending the Lifespan of Footwear

The future of sustainable footwear also involves designing products with a focus on longevity and repairability. This approach encourages consumers to take better care of their footwear, extending its lifespan and reducing the demand for frequent replacements. By creating durable and repairable products, companies can contribute to a circular economy model, minimizing waste and maximizing resource utilization. Designing footwear that is easy to repair and maintain reduces the need for frequent replacements, helping to lower the overall environmental impact.

Implementing strategies for recycling and repurposing used footwear is another key element of this circular economy. Creating a system for collecting and recycling footwear materials will close the loop and allow for the reuse of valuable resources. This strategy will ultimately decrease the environmental impact of the footwear industry, fostering a more sustainable future for the industry and its consumers.