The Science of Textile Recycling: Processes and Progress

Mechanical recycling is a prevalent method for processing textiles, focusing on separating and cleaning materials for reuse in new products. This process typically involves shredding, cleaning, and sorting textiles to recover fibers for use in various applications, like carpet backing or insulation. It's a relatively accessible and cost-effective method, but its effectiveness is limited to the quality of the input materials.

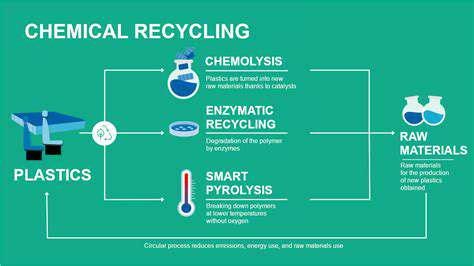

Chemical Recycling: Opening Doors to Complex Materials

Chemical recycling offers a more advanced approach to textile recycling, breaking down textiles into their constituent components at a molecular level. This process can handle a wider range of materials, including blends and complex fabrics, which are often challenging to recycle using mechanical methods. However, this technique often requires specialized equipment and chemical processes, making it more complex and potentially more expensive than mechanical recycling.

Innovative Textile Recycling Technologies

Ongoing research and development in textile recycling technologies are exploring novel approaches to address the limitations of current methods. These innovations include advancements in sorting techniques, chemical treatments, and the use of enzymes to break down complex fibers. These promising technologies hold the key to processing a broader range of materials and achieving higher recycling rates.

From advanced sorting algorithms to bio-based chemical treatments, the future of textile recycling is brimming with possibilities. These new technologies are crucial to increasing the efficiency and effectiveness of the textile recycling process.

The Role of Consumer Behavior in Textile Recycling

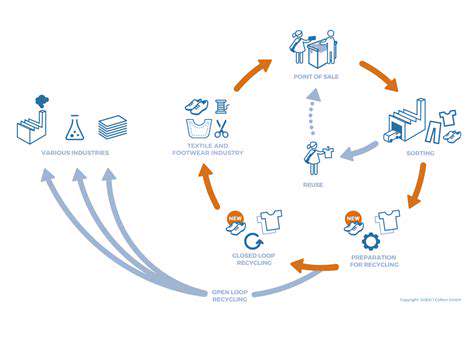

Consumer behavior plays a critical role in driving the success of textile recycling initiatives. Promoting awareness about the importance of textile recycling, encouraging consumers to choose durable and reusable clothing, and supporting responsible textile production practices are all essential elements of a comprehensive solution. Consumers can actively contribute to a more sustainable textile industry by making conscious choices about what they buy and how they dispose of their old garments.

Economic and Social Benefits of Textile Recycling

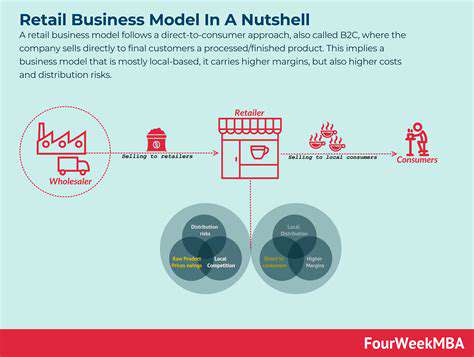

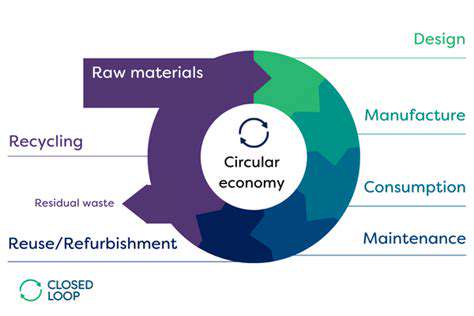

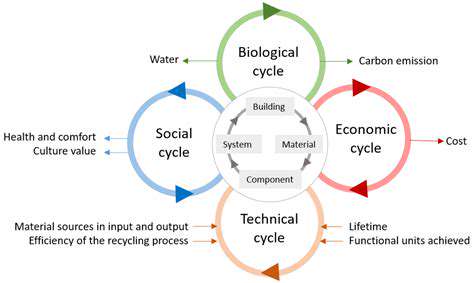

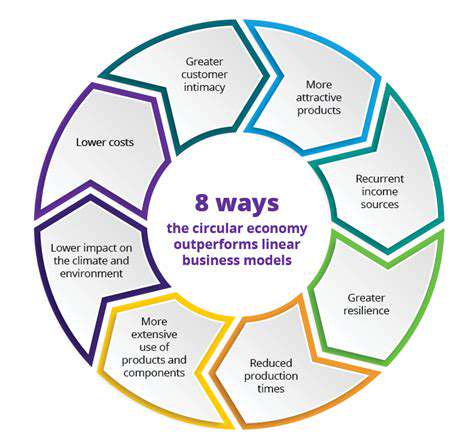

Textile recycling offers significant economic and social benefits. It reduces reliance on virgin resources, creating new markets for recycled materials and jobs within the recycling sector. Furthermore, textile recycling conserves natural resources, reducing the environmental impact of textile production and promoting a circular economy. The shift towards a circular economy model is not only environmentally beneficial but also offers significant economic opportunities, creating jobs and fostering sustainable development.

Mechanical Recycling: A Foundation for Textile Recovery

Mechanical Recycling Fundamentals

Mechanical recycling, a cornerstone of the circular economy, involves physically breaking down materials into usable components. This process typically involves shredding, grinding, and washing to remove contaminants. The key here is to maintain the material's original form as much as possible, allowing for its direct reuse in the manufacturing process. This process is crucial for reducing material waste and conserving resources. It's a cost-effective and relatively straightforward approach to recycling, making it an essential component of many recycling programs.

The effectiveness of mechanical recycling heavily depends on the quality of the input materials. Contaminants, such as food scraps, plastic bags, or other non-recyclable materials, can disrupt the process and compromise the quality of the recycled product. Proper sorting and pre-processing steps are critical to ensure a high-quality output that meets the standards of the manufacturing industry. This meticulous process ensures that the recycled material can be effectively reused, minimizing environmental impact and maximizing efficiency.

Types of Mechanical Recycling Processes

Various mechanical recycling methods are employed depending on the material being processed. For example, paper recycling typically involves pulping and deinking to separate fibers and remove ink. Plastic recycling often involves shredding and sorting to separate different types of plastics. Metal recycling commonly involves shredding and melting to recover the metal for reuse. Each process has unique requirements and considerations, from the initial sorting of materials to the final product specifications.

Different materials require different processing techniques to achieve optimal results. The selection of the appropriate process is essential to ensuring the quality of the recycled material and its suitability for various applications. This attention to detail ensures that the recycled product can be effectively integrated into the manufacturing process, contributing to sustainable practices.

Challenges and Future of Mechanical Recycling

Despite its advantages, mechanical recycling faces certain challenges. One significant hurdle is the issue of contamination, as mentioned earlier. Improper sorting can lead to the rejection of entire batches of materials, reducing overall recycling rates. Another concern is the limited recyclability of certain materials, particularly complex blends or composites. Furthermore, the energy consumption associated with some mechanical recycling processes can be a consideration. However, advancements in sorting technologies and improved processing techniques are promising to overcome these limitations.

The future of mechanical recycling lies in innovation and technological advancements. Research into new sorting technologies, such as advanced optical sorting and AI-driven systems, promises to improve the efficiency and accuracy of the process. Furthermore, ongoing research into material recovery and processing methods could expand the range of materials that can be effectively recycled mechanically. This will further cement the role of mechanical recycling in a circular economy, leading to greater resource conservation and a more sustainable future.

The Future of Textile Recycling: Innovation and Collaboration

Innovative Materials for Textile Recycling

The future of textile recycling hinges on the development of innovative materials and techniques. Researchers are exploring bio-based polymers and alternative fibers derived from agricultural waste and sustainable sources. This shift towards more readily recyclable materials will significantly impact the industry's environmental footprint, reducing reliance on petroleum-based textiles and enabling a circular economy approach to clothing production and consumption.

One promising area is the development of biodegradable polymers that mimic the properties of traditional fabrics while decomposing naturally. This could revolutionize the way we think about textile waste, transforming it from a problem into a valuable resource.

Advanced Recycling Technologies: Breaking Down the Complexities

Current recycling methods often struggle with the complex composition of modern textiles, which frequently include a blend of different fibers and synthetic materials. New technologies are being developed to address these challenges. These advancements include advanced mechanical sorting, chemical depolymerization, and enzymatic treatments, capable of breaking down even the most complex blends into reusable components.

Further research and development in these areas will unlock the potential for greater textile recycling rates, reducing the reliance on virgin resources and minimizing landfill waste.

The Role of Consumer Behavior in Textile Recycling

While technological advancements are crucial, consumer behavior plays a vital role in the success of textile recycling initiatives. Educating consumers about the importance of textile recycling and providing convenient collection methods are essential steps in driving participation. Encouraging the adoption of sustainable consumption patterns, such as repairing and repurposing clothing, is equally vital.

Clearer labeling and communication strategies regarding the recyclability of different fabrics will empower consumers to make informed choices, contributing significantly to the overall success of the textile recycling process.

Collaboration Between Industries and Governments

Successful textile recycling necessitates collaboration between various stakeholders, including textile manufacturers, retailers, recycling facilities, and government agencies. Joint ventures and partnerships will facilitate the development and implementation of efficient recycling infrastructure, optimizing resource allocation and maximizing the potential of recovered materials.

Government policies and incentives can encourage the adoption of sustainable practices, driving investment in recycling technologies and infrastructure. This collaborative effort is fundamental to achieving a truly circular economy for textiles.

The Economic Advantages of Textile Recycling

Investing in textile recycling offers significant economic advantages. The recovery of valuable materials like fibers and dyes from recycled textiles can reduce the cost of raw materials for new production, fostering a more sustainable and cost-effective textile industry. This creates new job opportunities in the recycling sector and stimulates economic growth.

The Environmental Impact of Textile Recycling

Textile recycling significantly reduces the environmental impact of the industry. By diverting textile waste from landfills, we lessen the strain on natural resources and minimize the release of harmful greenhouse gases associated with the production of virgin fibers. This, in turn, contributes to a healthier planet and a more sustainable future.

The conservation of water and energy resources during the recycling process further underscores the environmental benefits of this crucial endeavor.

The Future of Fashion: Design for Disassembly and Circularity

Moving towards a circular economy necessitates a fundamental shift in the way we design and produce textiles. Design for disassembly principles, incorporating readily separable materials and components, will allow for easier and more effective recycling processes. This approach will be crucial in maximizing the life cycle of clothing items and minimizing waste.

Furthermore, fostering a culture of responsible consumption and promoting the use of durable and repairable clothing will be critical for creating a truly sustainable fashion industry.