Textile Recycling Programs: Where Do Your Old Clothes Go?

Pre-Sorting and Material Separation

Textile recycling programs often begin with the crucial pre-sorting stage. This initial phase involves separating various textile materials, such as cotton, polyester, nylon, and wool, from mixed waste streams. This meticulous process is essential for ensuring that different fibers can be processed efficiently and effectively, preventing contamination that could compromise the quality of the recycled materials. Proper pre-sorting significantly impacts the end-product quality and sustainability of the recycling process, and it's a critical step to achieve the goal of transforming waste into valuable resources.

Different textile materials react differently to processing methods, and separating them before further processing is vital. This careful sorting process often relies on human labor, but advancements in automated sorting technologies are emerging to improve efficiency and accuracy. The goal of these technologies is to reduce the reliance on manual labor while increasing the speed and precision of separation, ultimately leading to higher recovery rates and a more sustainable recycling process.

Mechanical and Chemical Processing

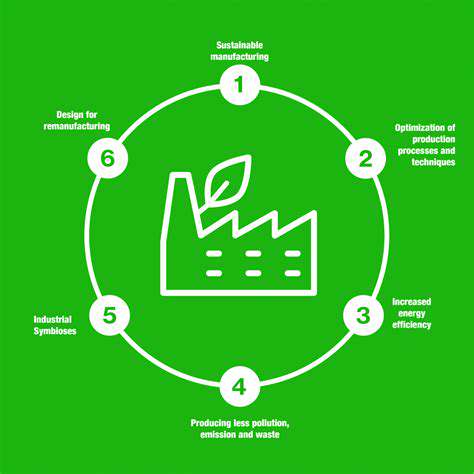

Once sorted, the textiles are subjected to mechanical and/or chemical processing methods to prepare them for reuse. Mechanical methods, such as shredding and baling, break down the textiles into smaller pieces and compact them for easier transport and processing. This process is crucial for preparing the materials for further manufacturing steps, creating a consistent raw material for new products. The mechanical processing methods can sometimes damage the fibers, however, leading to the need for chemical processes to enhance the quality of the recycled materials.

Chemical treatments can be employed to further refine the recycled materials. These treatments can remove contaminants, such as dyes or adhesives, and improve the quality of the fibers for use in new textiles. The choice between mechanical and chemical methods depends on the type of textile and the desired outcome. The combination of mechanical and chemical methods offers a powerful approach to recycling, enabling the creation of high-quality, reusable materials from a variety of textile sources.

Transforming Waste into New Products

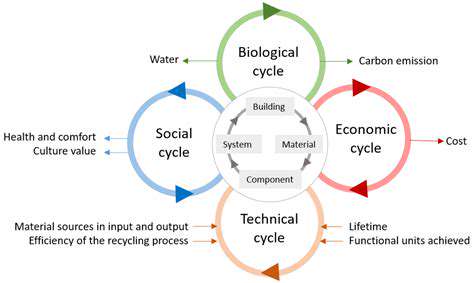

The recycled textile materials are then prepared for manufacturing new products, a crucial step in the recycling journey. The quality of the recycled materials influences the types of products that can be created. For example, high-quality recycled fibers can be used to create new clothing items, while lower-quality materials might be used in upholstery or insulation materials. This transformation from waste to new products demonstrates the potential of textile recycling programs to reduce landfill waste and create a circular economy.

The recycled materials, after processing, can be used in a wide range of applications, from creating new textiles to producing industrial materials. This transformation of waste into new products reduces the need for virgin resources, conserving raw materials and minimizing environmental impact. The demand for recycled materials is growing, and this demand is driving innovation in textile recycling programs, leading to more sustainable practices.

The Importance of Consumer Responsibility

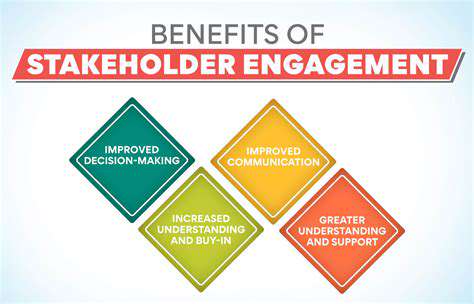

Consumer behavior plays a significant role in the success of textile recycling programs. Consumers can contribute to the efficiency of these programs by properly sorting textiles at the source, ensuring that recyclable materials are separated from non-recyclable items. This initial step is critical in ensuring that the materials can be effectively processed and transformed into new products.

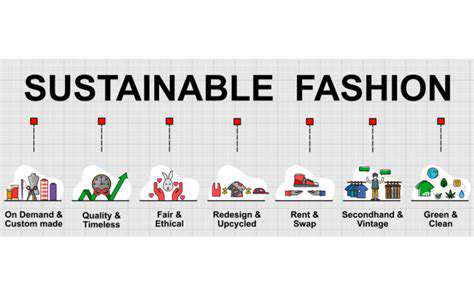

Understanding the different types of textiles that can be recycled, and ensuring that they are handled correctly, is essential. Consumers can contribute to the success of these programs by supporting brands that prioritize sustainability and implement effective recycling programs. This demonstrates the crucial link between consumer choices and the overall success of textile recycling initiatives.