The Environmental Footprint Comparison: Recycled vs Virgin Materials

Introduction to the Material Dilemma

Understanding the Core Concepts

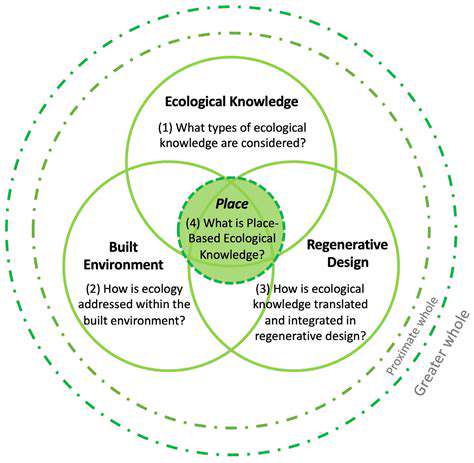

The material dilemma, a pervasive challenge in modern design and engineering, arises from the inherent trade-offs between various material properties. Different materials possess unique characteristics, such as strength, durability, weight, cost, and environmental impact. Choosing the optimal material for a specific application often necessitates careful consideration of these competing factors. Understanding these trade-offs is crucial for making informed decisions in product development and innovation.

This fundamental conflict highlights the need for a nuanced approach to material selection. A thorough understanding of the specific requirements of a project, alongside an awareness of the available material options, is essential for successful material selection. By recognizing the limitations and potential of different materials, designers and engineers can effectively mitigate risks and optimize performance.

Material Properties and Their Significance

Material properties are the defining characteristics that dictate how a material will behave under different conditions. Tensile strength, for example, measures a material's ability to withstand pulling forces, while hardness indicates its resistance to indentation. These properties are crucial in determining a material's suitability for various applications, from aerospace components to everyday consumer products. Understanding the interplay between different properties is essential for selecting materials effectively.

Analyzing the properties of different materials is crucial in determining their suitability for specific applications. The inherent characteristics of each material, such as stiffness, density, and thermal conductivity, must be evaluated in relation to the demands of the project. For example, a material with high stiffness might be suitable for structural components, while a material with low density might be preferable for lightweight applications.

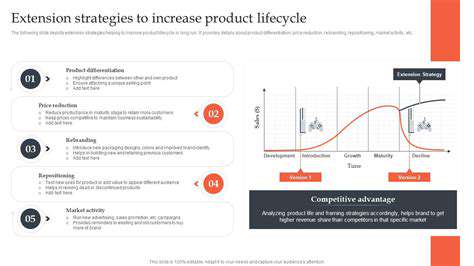

Material Selection Criteria

Several factors influence the selection of a particular material. Cost is a significant consideration, as different materials have varying price points, which directly impact the overall cost of the product. Availability and accessibility of the material are also important factors, ensuring that the chosen material is readily obtainable in the necessary quantities. Environmental impact is an increasingly important consideration, as environmentally friendly materials are gaining popularity.

The desired performance characteristics of the product heavily influence the choice of material. Factors such as strength, durability, and resistance to corrosion or wear must be carefully evaluated in relation to the anticipated usage conditions. These factors will dictate the chosen material and will directly impact the overall performance of the product. Furthermore, the aesthetic considerations for the product may also play a role in material selection.

Case Studies in Material Dilemmas

Analyzing real-world case studies provides valuable insights into the complexities of material selection. Take, for example, the development of lightweight yet strong aircraft components. Engineers face a trade-off between weight reduction and structural integrity. Advanced composites have emerged as a promising solution in this context, offering enhanced strength-to-weight ratios compared to traditional materials.

Another compelling example is the growing interest in sustainable materials for packaging applications. The need to reduce environmental impact necessitates the exploration of alternative materials, such as plant-based polymers. This shift highlights the increasing importance of environmental consciousness in material selection, leading to innovative solutions that balance performance with sustainability.

Future Trends and Innovations

The field of materials science is constantly evolving, presenting new opportunities and challenges. Advancements in nanotechnology offer the potential for creating materials with unprecedented properties, opening new avenues for innovation in diverse fields. These advancements could revolutionize the way we approach material selection and application.

The increasing demand for sustainable materials is driving research and development efforts toward bio-based and recycled materials. These innovations aim to reduce the environmental footprint of manufacturing and product lifecycles. This trend is expected to continue, as environmental concerns become more prominent.