The Global Movement Towards Sustainable Fashion: New Progress

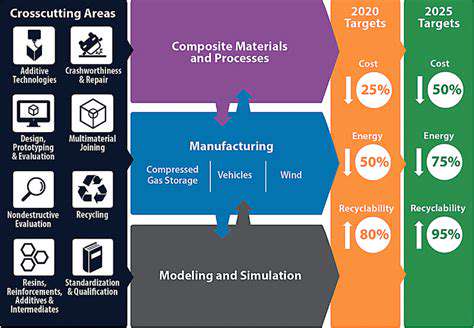

Advanced Polymer Composites

Polymer composites are revolutionizing numerous industries by offering a unique blend of properties. These materials combine the desirable characteristics of polymers, such as low weight and ease of processing, with the strength and stiffness of reinforcing fillers. This synergistic effect results in materials with exceptional performance, opening up possibilities for lightweight yet robust structures, leading to significant advancements in sectors like aerospace and automotive.

The development of advanced polymer composites involves careful selection and optimization of both the polymer matrix and the reinforcing fillers. Different types of polymers, such as epoxy resins or polyesters, are tailored to specific applications, while the choice of fillers, such as carbon fibers or glass fibers, significantly impacts the final material properties. This meticulous approach to material design enables engineers to achieve desired levels of strength, stiffness, and durability.

3D Printing for Customized Manufacturing

Additive manufacturing, particularly 3D printing, is transforming production processes. It allows for the creation of complex geometries and customized parts with unparalleled precision. This technology enables the production of intricate components that were previously impossible or economically infeasible to manufacture using traditional methods.

The use of 3D printing in prototyping and production is expanding rapidly. This includes applications in medical implants, aerospace components, and consumer goods. The ability to quickly and easily produce custom parts is revolutionizing the way products are designed and manufactured. The flexibility of 3D printing also allows for rapid iteration and adaptation based on customer feedback or evolving design requirements.

Sustainable Manufacturing Practices

The focus on sustainability is driving innovation in materials and production methods. Emphasis is placed on reducing the environmental footprint of manufacturing processes. This includes sourcing sustainable materials, minimizing waste generation, and optimizing energy consumption during production.

Sustainable manufacturing practices are not just environmentally responsible; they also often improve efficiency and reduce costs in the long run. Implementing these practices ensures that production processes have a smaller impact on the environment while maintaining a high level of quality and productivity.

Bio-Based Materials and Processes

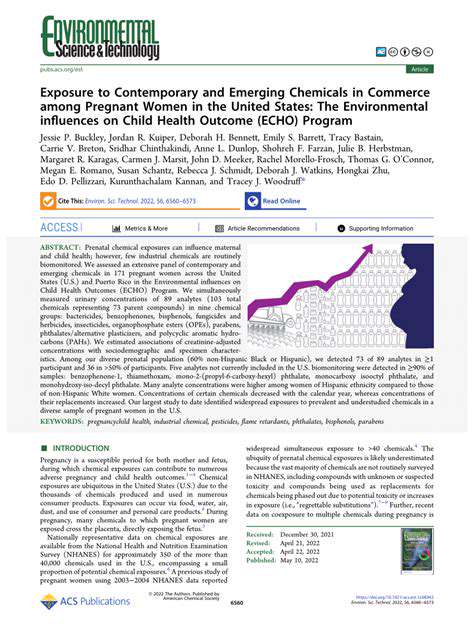

The exploration of bio-based materials and processes is gaining significant momentum. These materials, derived from renewable sources like plants and agricultural byproducts, offer a pathway towards more environmentally friendly manufacturing. This trend is driven by the need to reduce reliance on fossil fuels and decrease the environmental impact of conventional materials.

Bio-based polymers and composites are being developed with the aim of replicating the performance of traditional materials, while potentially offering enhanced biodegradability and recyclability. This is crucial for creating a more circular economy and moving away from a linear, take-make-dispose model.

Smart Materials and Sensors

Integrating smart materials and sensors into production processes is leading to increased efficiency and quality control. These materials can monitor and respond to various environmental factors, such as temperature or stress, providing valuable data for optimization and maintenance. The application of this technology is expanding the possibilities for predictive maintenance and proactive troubleshooting.

Smart materials, often incorporating embedded sensors, can monitor the condition of products or structures throughout their lifespan. This proactive approach enables early detection of potential issues, minimizing downtime and maximizing the lifespan of the products. This data-driven approach to manufacturing is revolutionizing quality control and efficiency.

Transparency and Traceability: Building Trust in the Supply Chain

Transparency in Building Materials

Transparency in the building materials industry is crucial for ensuring ethical sourcing and responsible production. This means providing clear and accessible information about the origin, composition, and manufacturing processes of materials. Consumers deserve to know the environmental impact of their choices, and manufacturers should willingly share this information. This includes details on energy consumption, water usage, and waste generation during the lifecycle of the product. Open communication about materials' sustainability credentials fosters trust and empowers informed purchasing decisions.

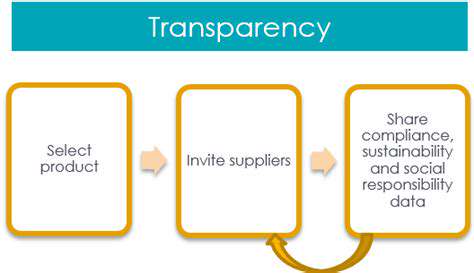

Furthermore, transparency extends to the supply chain. Knowing where materials come from, the labor conditions involved in their extraction or processing, and the environmental regulations followed is vital. This fosters a fairer and more sustainable industry, by encouraging accountability and reducing the risk of unethical practices. Consumers are increasingly demanding this level of openness and traceability, which directly influences purchasing behaviours.

Traceability in Construction Processes

Traceability in construction processes encompasses the ability to track materials, labor, and activities throughout the project lifecycle. This detailed record-keeping offers a valuable tool for identifying potential issues and improving quality control. By documenting every step from material procurement to final installation, construction companies can pinpoint any problems efficiently. This detailed record-keeping also allows for efficient problem resolution.

A robust traceability system allows for better project management and cost control. It enables quick identification of delays or deviations from the planned schedule. This crucial information allows for proactive adjustments to the project timeline and budget, mitigating potential financial losses. Furthermore, a transparent and traceable system ensures compliance with building codes and regulations by providing a clear audit trail.

Building a Sustainable Future Through Transparency and Traceability

Implementing transparency and traceability in the building sector is not just a matter of best practice; it's a critical step toward a more sustainable future. By providing detailed information about materials and processes, manufacturers and builders can empower consumers to make informed choices. This fosters greater accountability throughout the supply chain, encouraging responsible practices and reducing negative environmental impacts.

A transparent and traceable system creates a culture of accountability, ensuring that all stakeholders are held responsible for their actions. This includes builders, suppliers, and even the consumers themselves. This collaborative approach is key to achieving greater sustainability in the construction industry and ensuring the long-term health of our built environment. Furthermore, this type of transparency and traceability helps to build trust and credibility within the industry, encouraging a move toward greater ethical and sustainable practices.

.top/Stress-Management-Retreats-Finding-Calm-in-Chaos>In today's hyper-connected world, it's easy to become overwhelmed by constant notifications and demands on our time. Taking regular breaks from technology can significantly improve mental well-being. Unplugging allows our minds to rest and process information without the constant stimulation, reducing stress and anxiety, and fostering a sense of calm and clarity.

The Role of Technology and Innovation in Driving Sustainable Fashion

The Technological Advancements Shaping Sustainable Practices

Technological innovations are revolutionizing the fashion industry, enabling more sustainable practices across the entire lifecycle of a garment. From material science breakthroughs to innovative manufacturing processes, technology offers exciting solutions to address the environmental and social challenges of traditional fashion. For example, 3D printing allows for customized designs and reduced textile waste, while bio-based materials offer a greener alternative to conventional fabrics. These advancements not only minimize the environmental footprint of fashion but also pave the way for a more ethical and responsible industry, fostering a circular economy where garments are designed for longevity and recyclability.

Beyond material innovation, technology plays a critical role in streamlining supply chains and enhancing transparency. Improved logistics and communication technologies are making it easier to track raw materials from origin to finished product, enabling greater accountability and reducing the impact of hidden labor practices. This traceability not only allows brands to ensure ethical sourcing but also empowers consumers to make informed purchasing decisions, driving demand for sustainable products and practices.

Innovation in Design and Production for Reduced Waste

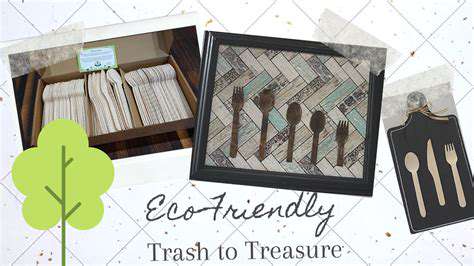

Sustainable fashion is no longer just about using eco-friendly fabrics; it encompasses innovative design and production processes. Designers are increasingly focusing on creating durable and repairable garments, minimizing waste throughout the design and manufacturing stages. This includes incorporating modular design principles, enabling garments to be easily customized, repaired, or repurposed. By fostering a culture of repair and upcycling, we can extend the lifespan of clothing and significantly reduce the demand for new production, thereby decreasing the environmental impact of the fashion industry.

Innovative production methods, such as the use of digital patterns and automated cutting, can optimize material use and reduce textile waste. These technologies, combined with advancements in dyeing and finishing processes, allow for more efficient and environmentally conscious manufacturing techniques. The future of sustainable fashion relies on a holistic approach that encompasses design, manufacturing, and consumption, all while prioritizing environmental responsibility.

Consumer Engagement and the Power of Data

The role of consumers in driving sustainable fashion is undeniable. Technology, through various platforms and applications, is empowering consumers to actively participate in the movement towards a more sustainable fashion industry. Online platforms that facilitate transparency and traceability allow consumers to understand the origins and ethical production of their clothing choices. This increased awareness and access to information allows consumers to make conscious decisions, supporting brands committed to sustainability and holding companies accountable for their practices.

Data analytics play a crucial role in understanding consumer preferences and behaviors related to sustainable fashion. By collecting and analyzing data, brands can gain insights into what consumers value and desire, enabling them to develop more sustainable products and marketing strategies that resonate with this growing market segment. This data-driven approach fosters a more responsive and customer-centric approach to sustainable fashion, driving innovation and growth within the industry while addressing consumer needs and expectations.

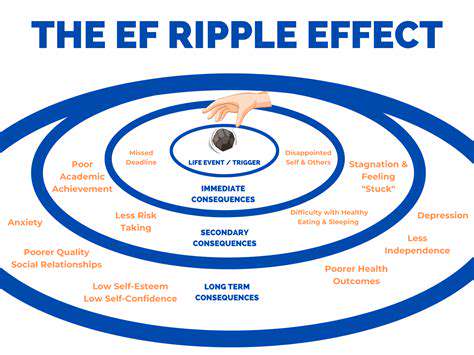

Furthermore, social media platforms provide a powerful tool for raising awareness and promoting sustainable fashion brands. Consumers can share their experiences and support ethical and environmentally conscious businesses through online engagement. This collective effort amplifies the message, encouraging more sustainable choices and creating a ripple effect within the broader fashion community.