The Ultimate Guide to Shopping for Recycled Clothing

Understanding the Growing Demand

Across the globe, people are showing a stronger preference for recycled clothing than ever before. This shift stems from multiple reasons, including heightened environmental consciousness and a collective effort to minimize textile waste. People aren't just following trends - they're making deliberate choices that reflect their values about sustainability. Additionally, with raw material costs climbing steadily, businesses are finding it increasingly practical to invest in textile recycling innovations.

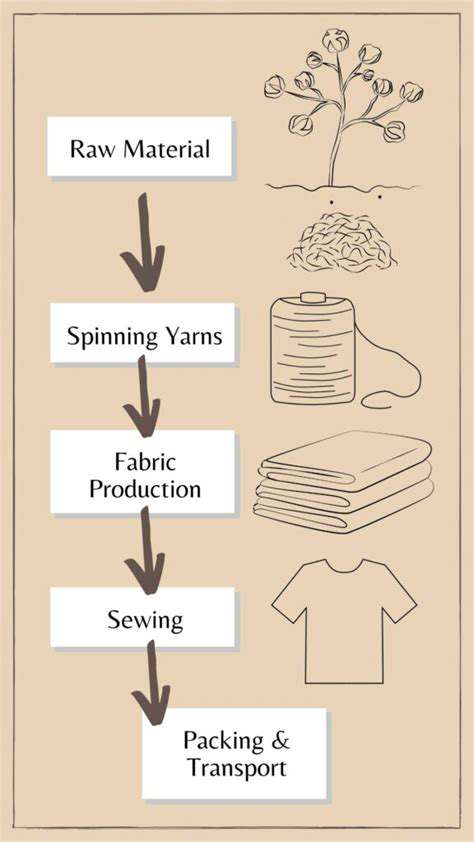

The Environmental Impact of Traditional Textiles

Conventional textile manufacturing, especially when using new materials, takes a heavy toll on our planet. These processes guzzle staggering amounts of water, consume massive energy reserves, and release toxic substances into ecosystems. Particularly problematic are synthetic fabrics like polyester, which can linger in landfills for centuries without breaking down. Such environmental consequences are accelerating the search for greener alternatives in the fashion industry.

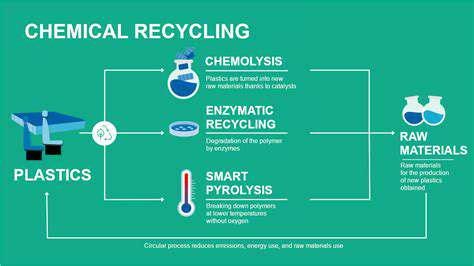

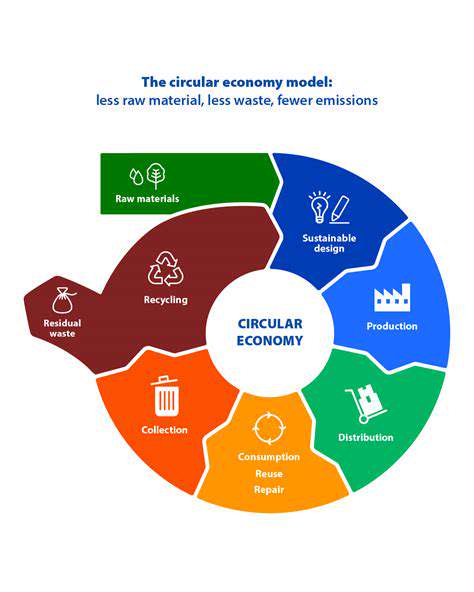

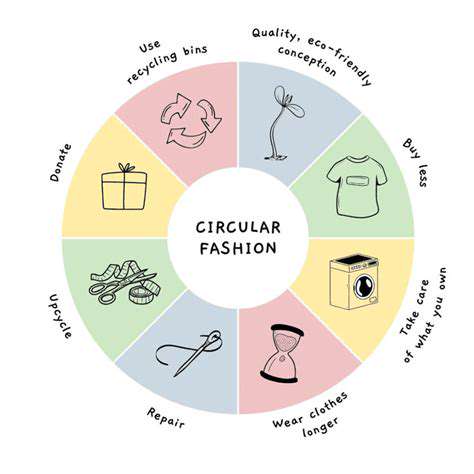

Innovations in Recycling Technologies

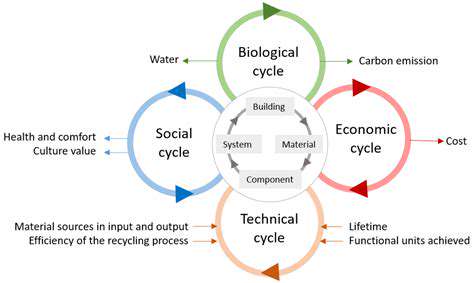

The field of textile recycling has seen remarkable technological breakthroughs recently. Modern techniques can now extract usable fibers from even the most complex fabric blends with impressive efficiency. These advancements represent more than technical achievements - they're fundamental building blocks for establishing a truly circular fashion economy. Entrepreneurs and researchers alike are finding exciting possibilities in these new methodologies.

Economic Opportunities in the Recycled Clothing Sector

This emerging market offers diverse economic prospects across the board. Whether it's launching eco-conscious fashion labels or pioneering novel recycling processes, there's room for creativity and commercial success. The sector's growth potential is enormous, perfectly aligning with worldwide sustainability initiatives. Forward-thinking investors are taking notice of this promising field.

Challenges and Considerations in Recycling

Despite its promise, clothing recycling faces several obstacles that need addressing. The varied composition of garments makes separation and processing particularly tricky. Maintaining high-quality standards for recycled materials is absolutely crucial for gaining consumer trust and industry adoption. Furthermore, many areas require substantial upgrades to their textile sorting and processing facilities to handle increased volumes effectively.

The Future of Recycled Clothing

Looking ahead, recycled clothing stands at the forefront of sustainable fashion's evolution. As technology continues advancing and consumer preferences shift toward eco-friendly options, this sector appears destined for remarkable expansion. The innovations we're seeing today may just be the beginning of a comprehensive transformation in how we produce and consume clothing, potentially leading to more inventive and sustainable designs than we've seen before.

Identifying Recycled Fabrics: A Fabricator's Guide

Understanding Recycled Fabric Composition

When working with recycled fabrics, the first essential step is grasping what they're made from. These materials can originate from surprising sources, ranging from discarded plastic containers to retired fishing gear. Recognizing the base components helps predict the fabric's behavior - its resilience, longevity, and ecological footprint. Since different recycling approaches yield distinct results, comprehending these processes proves invaluable.

It's worth noting that recycled fabrics vary significantly in composition. Some combine recycled elements with new materials, which directly influences both performance characteristics and pricing. Careful examination of product labels and material specifications remains essential for determining precise recycled content percentages.

Visual and Textural Characteristics

Recycled fabrics often display unique visual signatures. Compared to virgin materials, they might exhibit slight color variations, textural inconsistencies, or unusual patterning - perhaps faint streaks, speckling, or weaving irregularities. A trained eye can detect these telltale signs through careful inspection.

The tactile experience also provides important clues. Fabrics made from recycled content frequently have a distinct hand-feel - sometimes slightly coarser or less uniform than conventional textiles. This is especially noticeable in materials derived from plastic bottles, which may retain subtle textural characteristics from their original form. Developing sensitivity to these tactile differences is key for accurate identification.

Identifying Recycled Fibers Through Testing

While visual and tactile analysis offers helpful preliminary information, more rigorous testing sometimes becomes necessary. Specialized laboratory techniques can precisely determine a fabric's chemical makeup, confirming recycled content and detailing its exact composition. Such analysis proves critical for understanding how materials will perform under specific conditions like heat exposure, friction, or moisture.

State-of-the-art methods including spectroscopy can identify particular recycled fiber types with remarkable accuracy. This capability becomes especially useful when dealing with blended materials or attempting to trace recycled components back to their original sources, whether post-consumer waste or industrial byproducts.

Understanding Recycled Fabric Certifications and Standards

Numerous certification programs exist to verify and quantify recycled content in textiles. These certifications serve as reliable indicators that fabrics meet established standards for sustainable production. Savvy fabricators pay close attention to documentation specifying both the percentage of recycled material and its origin - information that's indispensable for maintaining ethical and environmentally responsible sourcing practices.

Analyzing Fabric Performance and Properties

Performance evaluation forms a critical part of working with recycled textiles. Depending on their origins and processing methods, these materials can demonstrate varying levels of strength, durability, and functional properties. Comprehensive testing under real-world conditions - including laundering, stretching, and sun exposure - provides crucial data about long-term viability.

By systematically assessing factors like resistance to tearing, dimensional stability, and color retention, professionals can make informed decisions about whether particular recycled fabrics suit their specific application requirements and quality standards.