From PET Bottles to Fashion: The Story of Recycled Polyester

Polyester's Diverse Applications

Polyester, derived from petroleum-based plastic, has evolved from a rigid synthetic material into a remarkably adaptable textile. Its journey spans clothing, furniture, industrial uses, and even medical equipment. The fabric's resilience, longevity, and ability to resist creasing make it indispensable in contemporary manufacturing. Unlike natural fibers, polyester maintains its integrity through repeated washing and wear, ensuring prolonged usability.

The Journey from PET Bottles to Fibers

Polyester originates as polyethylene terephthalate (PET), the same plastic used in water and soda bottles. Through a meticulous chemical process, PET's molecular structure undergoes controlled breakdown and realignment. These reconfigured polymers are then extruded into fine strands, ready for spinning. This transformation turns single-use plastics into durable threads capable of withstanding years of use. The precision required in this conversion highlights the intersection of chemistry and textile engineering.

Manufacturing Polyester Fibers: A Detailed Look

Creating polyester fibers demands exacting standards at every phase. Purified terephthalic acid combines with ethylene glycol under precise heat conditions to form the base polymer. This molten substance gets forced through spinnerets, emerging as hair-thin filaments. These strands undergo stretching and treatment to enhance tensile strength and dye receptivity. Variations in these processes yield everything from silky chiffons to rugged outdoor fabrics. The ability to fine-tune these characteristics explains polyester's dominance across multiple industries.

Polyester's Impact on the Fashion Industry

Walk through any clothing retailer, and polyester's prevalence becomes immediately apparent. Its cost-effectiveness and practical benefits have revolutionized apparel manufacturing. Activewear relies on its moisture-wicking properties, while fast fashion leverages its affordability. Unlike cotton, polyester garments retain their shape after countless washes, reducing replacement frequency. This durability paradoxically contributes to both its popularity and environmental challenges, as discarded polyester items accumulate in landfills.

Environmental Concerns and Sustainability Efforts

Polyester's petroleum origins pose significant ecological questions. The extraction and processing of fossil fuels for virgin polyester carry heavy carbon costs. However, industry innovators are responding with promising solutions. Forward-thinking companies now transform discarded plastic bottles into high-performance fabrics, diverting waste from oceans and landfills. Experimental plant-based alternatives and enhanced recycling technologies continue emerging, suggesting a greener future for this versatile material.

Polyester's Role in Diverse Industries

Beyond wardrobes, polyester proves invaluable in unexpected sectors. Its exceptional strength-to-weight ratio makes it ideal for marine ropes capable of withstanding saltwater corrosion. Automotive manufacturers incorporate polyester resins into dashboards and body panels for their impact resistance. In healthcare, sterile polyester fabrics serve as protective barriers in surgical settings. This cross-industry applicability demonstrates how a single material can address vastly different performance requirements.

Future of Polyester: Innovations and Advancements

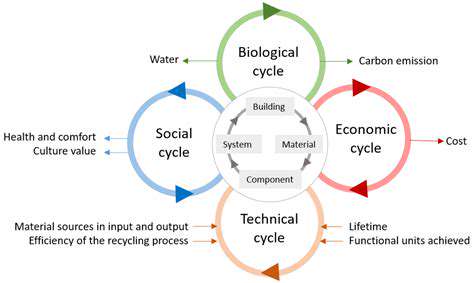

The next chapter for polyester involves groundbreaking sustainable developments. Scientists are experimenting with enzymatic recycling to break down fabrics at molecular levels without quality loss. Some labs cultivate polyester-like fibers from agricultural waste, offering carbon-negative alternatives. These innovations aim to preserve polyester's desirable qualities while eliminating its environmental drawbacks. As technology progresses, we may witness a new era where performance textiles coexist harmoniously with planetary health.

The Environmental Benefits of Recycled Polyester

Reduced Greenhouse Gas Emissions

Recycled polyester slashes greenhouse emissions by up to 75% compared to virgin production. Traditional polyester manufacturing involves energy-intensive fossil fuel processing, releasing significant CO2. The recycling process skips these initial steps, dramatically cutting carbon output. This reduction proves critical for fashion brands committed to science-based climate targets. Moreover, recycled polyester facilities increasingly utilize renewable energy, further diminishing their carbon footprint.

Conservation of Natural Resources

Every ton of recycled polyester conserves approximately 20,000 liters of water and eliminates the need for 1.5 tons of crude oil. These savings protect vulnerable ecosystems from drilling and fracking operations. By diverting PET bottles from waste streams, we simultaneously reduce petroleum demand and plastic pollution. This dual benefit creates a compelling case for scaling recycled polyester adoption across industries.

Waste Reduction and Landfill Mitigation

Synthetic textiles account for nearly 60% of clothing materials but can take centuries to decompose. Recycling transforms this persistent waste into valuable raw material. Advanced sorting technologies now efficiently separate polyester blends, enabling circularity for previously unrecyclable fabrics. Some innovative programs even repurpose ocean plastics into high-end activewear, addressing marine pollution while creating premium products.

Water Conservation

Virgin polyester production consumes vast water quantities for cooling and processing. Recycling requires minimal water by comparison - primarily for cleaning collected materials. In drought-prone regions where textile manufacturing concentrates, this water savings preserves drinking supplies and maintains aquatic ecosystems. Some facilities implement closed-loop water systems, continuously filtering and reusing processing water for near-zero discharge.

Improved Air Quality

Petrochemical plants emitting volatile organic compounds (VOCs) often surround communities with elevated respiratory illness rates. Recycled polyester production generates 75% fewer air pollutants than conventional methods. This cleaner process benefits both factory workers and nearby residents, particularly in manufacturing-intensive regions. As recycling technologies advance, these air quality improvements will likely expand further.

Lower Carbon Footprint

The comprehensive environmental assessment reveals recycled polyester's clear advantages. From raw material sourcing to final product, the recycled variant demonstrates superior sustainability metrics. Lifecycle analyses confirm its reduced impact across all measured categories - carbon, water, energy, and pollution. These compelling data points drive major brands to incorporate recycled content into their sustainability commitments.

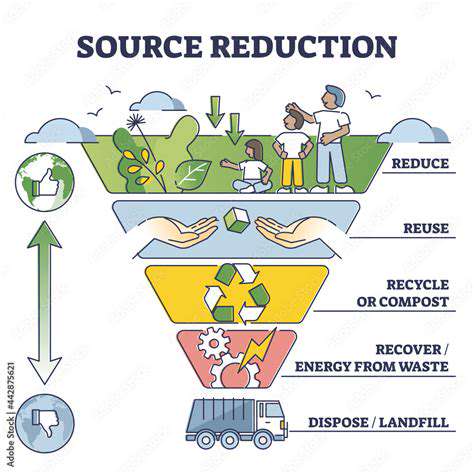

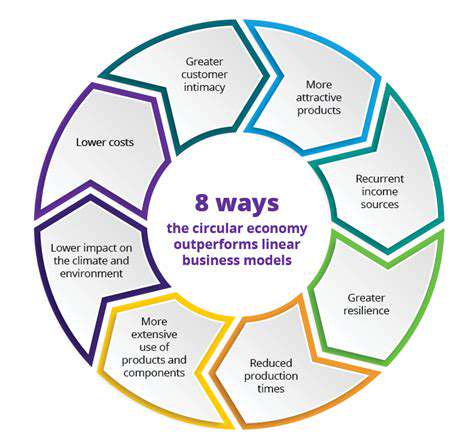

Economic Benefits and Circular Economy

Recycling infrastructure creates localized job opportunities in collection, sorting, and processing. The Ellen MacArthur Foundation estimates the circular economy could generate $700 billion annually in material savings for the fashion industry. This economic potential, combined with environmental benefits, makes recycled polyester a cornerstone of sustainable development strategies. Consumer demand for circular products continues rising, incentivizing further investment in recycling technologies.

The Future of Sustainable Fashion: Embracing Recycled Materials

Circular Economy Principles in Sustainable Fashion

The fashion industry's future lies in closing the loop on material flows. Leading brands now design garments considering their eventual disassembly and recycling. Modular designs with mono-material components simplify recycling while maintaining aesthetic appeal. Some labels offer repair services and take-back programs, keeping clothing in use longer and recovering materials at end-of-life.

Technological Advancements in Sustainable Materials

Material science breakthroughs yield astonishing alternatives - from algae-based yarns to self-repairing fabrics. These innovations don't merely match conventional materials but often surpass them in functionality. For instance, some bio-fabrics naturally regulate temperature better than synthetics while being fully compostable. Investment in these technologies continues accelerating as sustainability becomes a competitive advantage.

Consumer Demand and Ethical Practices

Modern shoppers increasingly scrutinize brands' sustainability claims, demanding proof of ethical sourcing and production. This shift has spawned new certification programs and blockchain-based traceability systems. Conscious consumers now influence market trends significantly, with searches for sustainable fashion increasing tenfold in recent years. Brands responding authentically to this demand gain loyal, engaged customer bases.

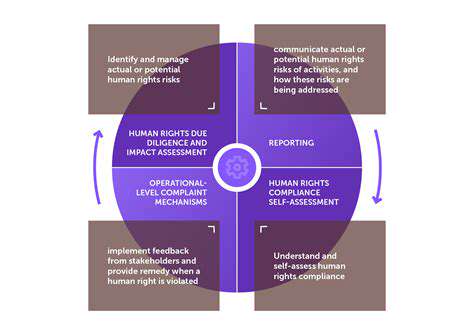

Transparency and Traceability in Supply Chains

Forward-thinking companies now map their entire supply chains, from raw material origins to retail shelves. Digital product passports containing detailed production information are becoming industry standards. This unprecedented transparency allows consumers to make fully informed purchasing decisions aligned with their values. Some apps even scan clothing tags to reveal the garment's environmental impact and worker conditions during manufacture.

The Role of Innovation in Sustainable Design

Designers now employ cutting-edge techniques like 3D knitting to eliminate fabric waste during production. Others experiment with natural dyes that require less water and energy than conventional options. These creative solutions demonstrate that sustainability constraints can spark remarkable innovation. The most successful designs merge ecological responsibility with desirability, proving environmentalism needn't compromise style.

Impact of Government Regulations and Policies

Legislative measures are reshaping industry practices worldwide. France bans destruction of unsold textiles, while New York proposes mandatory climate disclosure for fashion companies. These policies create a level playing field where sustainability becomes non-negotiable rather than optional. Such regulations also stimulate green job creation and technological development in sustainable textiles.

The Importance of Collaboration and Partnerships

No single entity can transform the fashion industry alone. Consortiums like the Sustainable Apparel Coalition unite competitors around shared environmental goals. These alliances pool resources for systemic change, from developing recyclable material standards to establishing global take-back programs. Even consumers participate through clothing swaps and rental platforms, collectively redefining fashion consumption.