The Business Case for Embracing Circularity: New Data

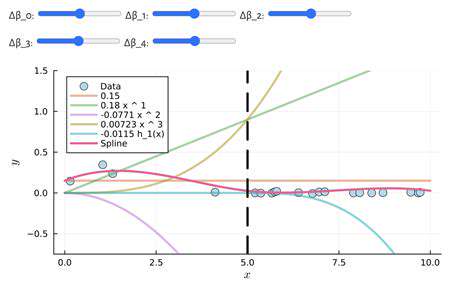

Designing for Disassembly and Material Recovery: Data-Driven Design

Designing for Disassembly: Why It Matters

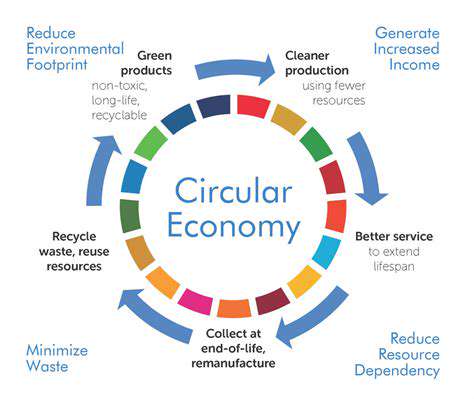

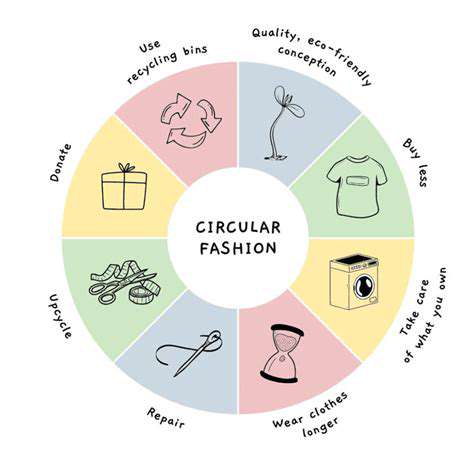

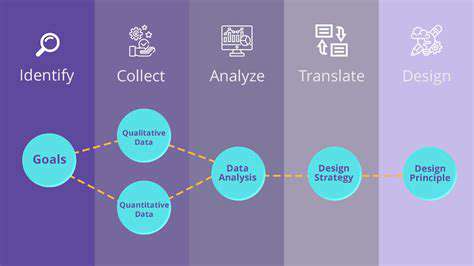

Designing products with disassembly in mind is crucial for sustainability and cost-effectiveness. By anticipating future disassembly needs, manufacturers can reduce the environmental impact of product disposal and potentially lower the cost of repairs and replacements. This forward-thinking approach fosters a circular economy, where products are designed to be easily taken apart, recycled, and reused.

A product's lifespan often extends beyond its initial use. Proper disassembly allows for the recovery of valuable materials, reducing the need for raw material extraction and minimizing waste sent to landfills. This environmentally conscious design philosophy minimizes the environmental footprint and promotes responsible resource management.

Understanding the Principles of Disassembly

Key principles in designing for disassembly include modularity, standardization, and the use of readily accessible fasteners. These principles facilitate the separation of components for easier recycling and reuse. Modular design allows for the replacement of individual components without needing to dismantle the entire product, improving the product's lifecycle and its overall value.

Standardization of parts across different products can significantly reduce the complexity of disassembly and increase the potential for component reuse. This approach is particularly beneficial for mass-produced items.

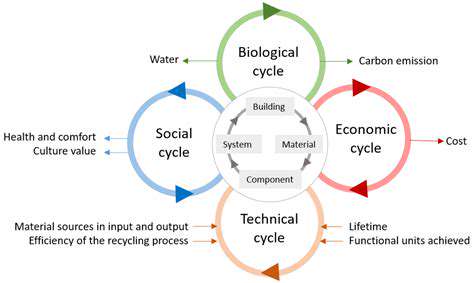

Material Selection and its Impact

The choice of materials plays a vital role in designing for disassembly. Using materials that are easily recyclable or reusable is essential for efficient product dismantling and subsequent material recovery. This strategy reduces the environmental impact associated with manufacturing and disposal.

Selecting materials that are compatible with recycling processes and that can be effectively separated during disassembly is key. This often requires considering the material's properties, such as its melting point, chemical composition, and physical structure, for optimal separation strategies.

Fastener Selection and Placement

Fasteners are crucial components in product assembly and disassembly. Choosing appropriate fasteners that are easily removable and do not damage the components during disassembly is essential for efficient product dismantling. Using standardized fasteners can also improve the efficiency of the process and reduce potential damage.

Careful consideration of fastener placement and type is vital. Secure and easy-to-remove fasteners are crucial for efficient and safe disassembly, which directly translates into lower costs and higher product lifecycle value.

Modular Design for Enhanced Flexibility

Modular design allows for the separation of components for easier maintenance, repair, and recycling. This approach promotes a more sustainable product lifecycle and reduces the need for complete product replacement. Each module can be designed with specific functionalities, allowing for flexibility in product configurations and updates.

Modular designs can be adapted to changing needs or technology advancements, which is particularly important in the constantly evolving technological landscape.

Sustainability and Environmental Impact

Designing for disassembly is a key aspect of promoting a circular economy, where materials are reused and recycled. This reduces the environmental impact of product disposal and fosters a more sustainable approach to manufacturing and consumption. By designing for disassembly, manufacturers can minimize waste and conserve resources.

Economic Benefits of Disassembly-Friendly Design

Designing for disassembly can lead to significant economic benefits. Lowering repair and maintenance costs, increasing product lifespan, and creating opportunities for material recovery are all positive outcomes. Efficient disassembly also reduces the need for raw material extraction, which can translate to lower production costs in the long run.

Companies that adopt these principles can improve their overall profitability and enhance their reputation as environmentally responsible organizations.