The Circularity of Denim: A Success Story in Sustainable Fashion

The Role of Recycled Denim: A Sustainable Solution

The Environmental Impact of Conventional Denim Production

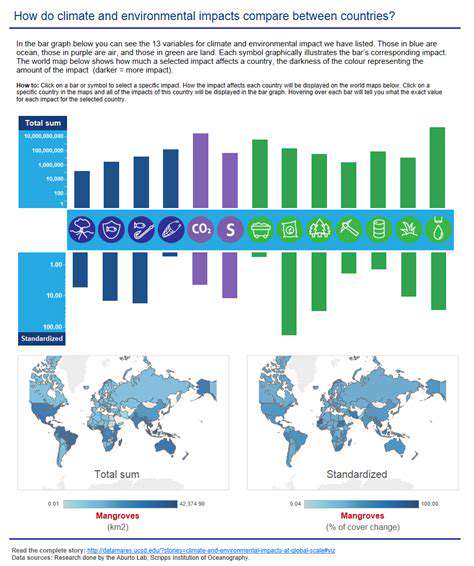

Traditional denim manufacturing has long been criticized for its excessive resource consumption. The process, from cotton cultivation to final garment production, requires staggering amounts of water and energy. Cotton farming alone accounts for nearly 2.5% of global agricultural water usage, while the dyeing process contributes to severe water pollution in manufacturing regions. These practices have led to measurable environmental degradation, including soil contamination and increased carbon emissions.

Many factories release untreated wastewater containing harmful chemicals into local waterways, affecting both ecosystems and nearby communities. This reality underscores why alternative production methods are not just preferable but necessary for the industry's survival.

Exploring the Benefits of Recycled Denim

Repurposed denim presents a viable solution to these environmental challenges. By giving old jeans new life, we reduce the demand for virgin cotton by up to 60% per garment. This approach directly addresses two critical issues: resource depletion and textile waste accumulation in landfills.

Interestingly, many recycled denim products actually outperform their conventional counterparts in durability tests. The re-processing of cotton fibers often results in a denser, more resilient fabric that withstands extended wear. This longevity naturally decreases the frequency of purchases, creating a positive cycle of reduced consumption.

The Circularity of Denim: A Sustainable Approach

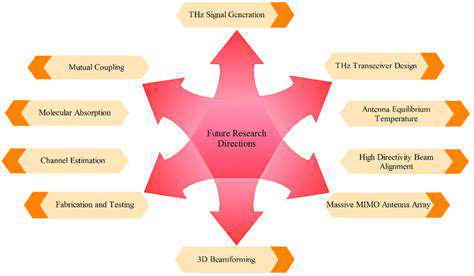

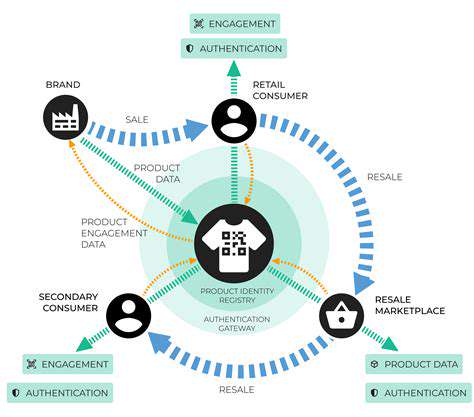

Modern recycling technologies now allow denim to complete full lifecycles without becoming waste. Advanced mechanical and chemical processes can break down used garments into reusable fibers, while some innovators are even creating new materials from denim dust. These breakthroughs demonstrate how circular economy principles can transform an entire industry.

Forward-thinking brands are implementing take-back programs where customers return old jeans for recycling credits. Such initiatives not only ensure proper material recovery but also educate consumers about sustainable practices.

The Economic Advantages of Recycled Denim

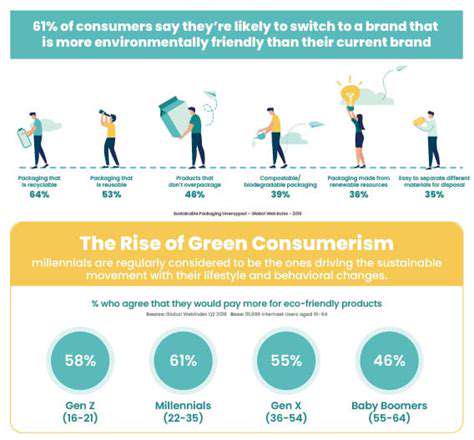

The market for sustainable fashion is expanding rapidly, with eco-conscious consumers willing to pay premiums for responsibly made products. Companies incorporating recycled materials often see improved brand perception and customer loyalty. Recent surveys indicate 73% of millennials prefer purchasing from environmentally responsible brands, creating significant financial incentives for adoption.

Operational costs for recycled denim production are decreasing as technology improves, making it increasingly competitive with conventional methods. Some manufacturers report up to 30% savings on raw material expenses after switching to recycled sources.

The Social Impact of Recycled Denim

Beyond environmental benefits, denim recycling initiatives frequently create meaningful social value. Many programs partner with vocational training centers, providing employment opportunities in sorting and processing facilities. These jobs often go to individuals facing employment barriers, offering stable income and skill development.

The Future of Sustainable Denim

Industry experts predict recycled content will become standard rather than exceptional in denim production. Emerging technologies like enzymatic fiber separation and waterless dyeing promise to further reduce the environmental footprint. The next decade will likely see complete supply chain transformations as sustainability shifts from niche to norm.

Consumer awareness continues growing, with social media accelerating demand for transparent, ethical fashion. This cultural shift pressures brands to adopt recycled materials not just for compliance, but for competitive survival.