The Future of Materials: Blending Bio based, Recycled, and Regenerative

Bio-Based Materials: A Sustainable Alternative

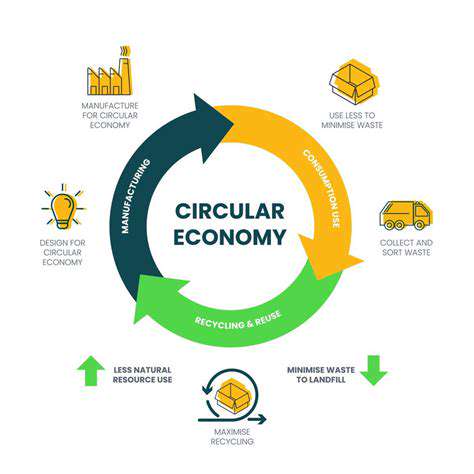

Bio-based materials offer a compelling alternative to traditional petroleum-derived plastics, presenting a crucial pathway towards a more sustainable future. These materials, derived from renewable resources like plants, algae, and agricultural byproducts, reduce reliance on finite fossil fuels and lessen the environmental impact associated with their production and disposal. The inherent renewability of these resources fosters a closed-loop system, minimizing waste and promoting circular economy principles.

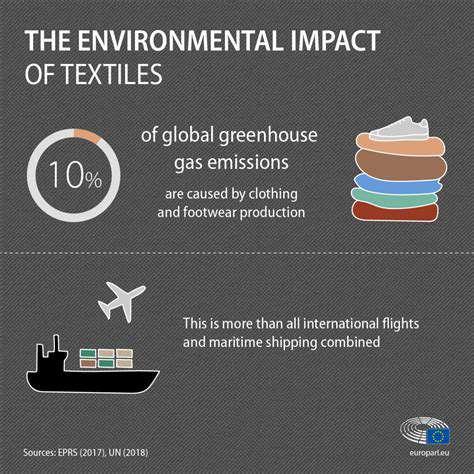

The potential for bio-based materials extends beyond plastic production. From construction materials to textiles and packaging, the versatility of these materials creates opportunities for innovation across numerous industries. This transition holds immense promise for reducing our environmental footprint and creating a more ecologically balanced approach to material science.

The Growing Demand for Bio-Based Solutions

The increasing awareness of environmental concerns, coupled with stringent regulations and consumer demand for sustainable products, is driving the growth of the bio-based materials market. Consumers are actively seeking eco-friendly options, placing a premium on products with reduced carbon footprints and minimized environmental impact. This rising demand fuels innovation and investment in research and development, further accelerating the transition towards a bio-based economy.

Governments and organizations worldwide are implementing policies and incentives to support the adoption of sustainable practices. These initiatives, including subsidies for bio-based materials and regulations on plastic waste, pave the way for a broader integration of bio-based solutions into various sectors of the economy. This supportive environment fosters further growth and encourages the development of novel applications for these materials.

Technological Advancements in Bio-Based Materials

Continuous advancements in biotechnology and material science are driving significant improvements in the performance and properties of bio-based materials. Researchers are exploring innovative techniques to enhance the strength, durability, and functionality of these materials, enabling their use in a wider range of applications. From genetically modified crops to enzymatic processes, scientists are developing more efficient and cost-effective methods for producing bio-based materials, making them increasingly competitive with conventional alternatives.

The development of novel bio-based polymers and composites is expanding the possibilities for these materials. These advancements include the creation of biodegradable plastics with enhanced mechanical properties, and bio-based fibers with superior thermal resistance. This ongoing research and development promises to unlock further potential for bio-based materials in the future.

Challenges and Future Outlook for Bio-Based Materials

Despite the numerous advantages, bio-based materials face certain challenges, including scalability of production, cost-effectiveness, and maintaining consistent quality. Overcoming these hurdles is crucial for widespread adoption and integration into existing industrial processes. Addressing these challenges requires collaborative efforts between researchers, industry partners, and policymakers to ensure sustainability and economic viability.

Looking ahead, the future of bio-based materials hinges on continued innovation, investment, and a unified commitment to sustainability. Collaboration between researchers, industry leaders, and policymakers will be vital in overcoming existing challenges and realizing the full potential of these materials in a greener future. The potential for bio-based materials to revolutionize various sectors remains vast.

The convergence of virtual and augmented realities is ushering in a new era of immersive experiences, blurring the lines between the physical and digital worlds. Users are no longer confined to passively consuming content; instead, they are actively participating in interactive environments that respond dynamically to their actions and presence. This dynamic interplay between the real and the virtual is revolutionizing various sectors, from gaming and entertainment to education and training, offering unprecedented possibilities for engaging and enriching experiences.

Regenerative Materials: Cultivating a Sustainable Cycle

Regenerative Materials: A Sustainable Approach

Regenerative materials represent a paradigm shift in material science, moving away from the linear take-make-dispose model towards a circular economy. This approach emphasizes the creation of materials that can be repeatedly utilized, repaired, or even regenerated, minimizing waste and environmental impact. This is crucial for the future of our planet, as traditional methods of resource extraction and manufacturing are unsustainable and contribute significantly to pollution.

By utilizing renewable resources and employing innovative recycling and upcycling techniques, regenerative materials aim to close the loop on material cycles. This also reduces our reliance on finite resources, fostering a more resilient and sustainable future for all.

Key Characteristics of Regenerative Materials

A defining characteristic of regenerative materials is their inherent ability to return to a usable state after use. This could involve processes like bio-based polymers that naturally decompose or metals that are easily recycled and reused. The focus is on creating products with a lifespan beyond a single use, promoting circularity and resource efficiency.

Another crucial characteristic is their design for disassembly and reuse. This means that the materials are designed in a way that facilitates their deconstruction and repurposing into new products, minimizing waste generation and maximizing material value.

Materials that are easily recycled and composted also fall under this category. These materials contribute to a closed-loop system where waste is transformed into valuable resources, creating a more sustainable and environmentally friendly approach to manufacturing and consumption.

Applications and Benefits of Regenerative Materials

The applications of regenerative materials are vast, spanning various industries. From packaging to construction, fashion to electronics, these materials hold immense potential for revolutionizing how we produce and consume goods. This shift towards regenerative materials not only addresses environmental concerns but also fosters economic opportunities and creates new job sectors.

The benefits extend beyond environmental sustainability. Regenerative materials can also significantly reduce manufacturing costs associated with resource extraction and processing. Reduced waste disposal expenses are a critical component of this economic advantage.

The development and implementation of regenerative materials are crucial for a more sustainable future and can have a positive impact on society and the environment. By embracing this paradigm shift, we can create a more resilient, resource-efficient, and environmentally conscious world.

The Synergistic Future: Blending for Enhanced Performance

Materials Convergence: A New Era

The future of materials is not about individual substances, but about the seamless integration and blending of diverse materials. This convergence, driven by advancements in nanotechnology and sophisticated synthesis techniques, promises to unlock unprecedented performance capabilities. Imagine materials that exhibit properties surpassing those of their constituent parts, offering a pathway to create lighter, stronger, more durable, and more efficient structures in various applications.

This paradigm shift marks a departure from traditional approaches, which focused primarily on optimizing individual materials. Instead, future research and development will revolve around the design and synthesis of composite materials with tailored functionalities. This innovative approach will empower engineers and designers to create solutions for complex challenges in diverse fields, from aerospace and automotive to energy and medicine.

Enhanced Performance Through Synergy

The synergistic effect arising from the blending of materials is a key driver behind this transformative approach. By carefully selecting and combining different materials, we can achieve a combined performance that exceeds the sum of the individual contributions. This phenomenon allows us to design materials with unique characteristics, exceeding the limitations of individual components.

For instance, combining a lightweight material with a high-strength material can create a structure that is both strong and efficient. This principle is already being applied in various industries, leading to significant improvements in efficiency and performance. The possibilities are vast, and the future holds exciting developments in material science.

Tailoring Properties for Specific Applications

One of the most significant advantages of this approach is the ability to tailor the properties of blended materials to specific applications. Imagine crafting a material specifically designed for high-temperature applications in aerospace, or developing a biocompatible material for advanced medical implants. The possibilities are nearly limitless.

Through meticulous research and development, we can achieve a level of precision in material design that was previously unimaginable. This precision will allow us to address intricate challenges across diverse industries, from creating advanced energy storage systems to developing sustainable and resilient infrastructure. The ability to fine-tune material properties is a game-changer for the future.

Challenges and Opportunities in Blending

While the potential of blending materials is immense, challenges remain in achieving optimal performance and scalability. Understanding and predicting the synergistic effects of different material combinations is a complex task that requires advanced modeling and experimentation.

Furthermore, the cost-effectiveness of producing these blended materials needs to be addressed to ensure widespread adoption. Despite these challenges, the opportunities for innovation and advancement are enormous. The future of materials holds the key to addressing some of the world's most pressing challenges and shaping a more sustainable and technologically advanced future.