The Future of Materials: Blending Bio based and Recycled Content

Harnessing the Power of Plant-Based Polymers

Bio-based materials offer a compelling alternative to traditional petroleum-based plastics, drawing inspiration from the vast array of natural polymers found in plants. These renewable resources, such as corn starch, sugarcane, and various plant fibers, can be chemically modified or processed to create a diverse range of materials with properties comparable to or even exceeding those of conventional plastics. This sustainable approach reduces reliance on finite fossil fuels, lowering the environmental footprint associated with plastic production. The potential for bio-based polymers extends far beyond packaging applications, offering opportunities for innovative solutions in construction, textiles, and electronics.

The development of bio-based materials is not without its challenges. Achieving consistent material properties and cost-effectiveness remains a significant hurdle. However, continuous research and advancements in biopolymer processing techniques are gradually overcoming these obstacles. As the demand for sustainable alternatives grows, significant investments in research and development are driving innovation in this field, promising a future where bio-based materials play a crucial role in various industries.

Exploring the Potential of Algae-Derived Materials

Algae, with its remarkable ability to absorb carbon dioxide from the atmosphere, presents a fascinating avenue for bio-based material production. Algae-based materials offer a unique opportunity for sustainable resource utilization, tapping into a fast-growing, renewable resource. The resulting materials exhibit remarkable properties, including biodegradability and enhanced strength, potentially revolutionizing sectors such as packaging and construction. The cultivation of algae for biomaterial production is a burgeoning field, with significant potential for large-scale applications.

Furthermore, algae-derived materials often possess unique functionalities, such as enhanced UV resistance or improved biocompatibility. These inherent properties could lead to the development of novel applications in diverse sectors, contributing to a more sustainable and resilient future. This emerging area of research is poised to significantly impact the materials landscape, offering a pathway toward a circular economy for biomaterials.

The Role of Fungi in Material Science

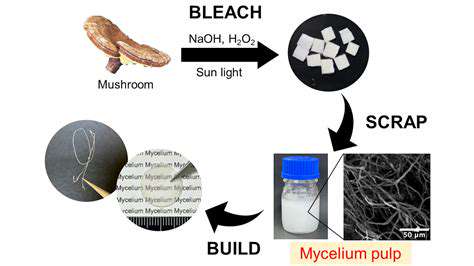

Fungi, with their remarkable ability to break down complex organic materials, are also emerging as a valuable resource for innovative bio-based materials. Mycelium, the vegetative part of a fungus, can be cultivated into intricate structures, offering a sustainable alternative to traditional materials like wood and plastic. These mycelium-based materials possess impressive characteristics, including exceptional strength, durability, and biodegradability, providing a viable solution for various applications, from packaging to construction.

The potential of fungi extends beyond the structural applications. The biodegradability of mycelium-based materials aligns perfectly with the growing global movement towards circular economy principles. This characteristic, coupled with the inherent biocompatibility of some fungal materials, opens doors to numerous applications in sectors ranging from medical implants to agricultural products. This exciting frontier in material science promises to deliver sustainable and innovative solutions.

The Future of Bio-Based Composites

Combining bio-based polymers with other natural fibers or fillers creates bio-based composites with enhanced properties. This approach leverages the strengths of both components, resulting in materials that are lighter, stronger, and more durable than their individual counterparts. This synergistic combination opens up exciting possibilities in various sectors, including automotive, aerospace, and construction, where the demand for lightweight and high-performance materials is ever-increasing.

The development of bio-based composites is crucial for achieving a more sustainable future. By incorporating natural fibers like bamboo or flax into biopolymer matrices, manufacturers can create materials with superior mechanical properties while reducing their environmental impact. This innovative approach is paving the way for a new generation of sustainable materials, contributing to a more circular and eco-friendly industrial landscape. Further research and development in this area will be vital in driving the widespread adoption of bio-based composites.

Recycled Content: Giving Life to Waste

Harnessing the Power of Recycling

Recycling isn't just about collecting and processing waste; it's about fundamentally changing our relationship with materials. By strategically reusing and repurposing existing resources, we can significantly reduce the strain on our planet's finite reserves. This shift towards a circular economy, where materials are continuously reused, is crucial for the future of our environment and our economies.

The process of recycling, from sorting and processing to transforming waste materials into new products, requires careful consideration and investment in sustainable technologies. This includes not only the physical process but also the development of innovative approaches to design for recyclability and the creation of robust recycling infrastructure.

Bio-based Alternatives: A Sustainable Solution

Bio-based materials offer a compelling alternative to traditional petroleum-based products. Derived from renewable sources like plants and agricultural byproducts, these materials provide a pathway to a more sustainable future, reducing our dependence on fossil fuels and minimizing our environmental footprint. The development and implementation of bio-based alternatives are critical to mitigating the effects of climate change and ensuring the long-term health of our ecosystems.

Exploring the potential of bio-based materials goes beyond simply replacing existing products. It encompasses the development of entirely new materials with enhanced properties, creating opportunities for innovation and economic growth in the sustainable materials sector. This includes research into bio-plastics, bio-composites, and other eco-friendly alternatives.

The Future of Materials Science: Blending Innovation and Sustainability

The future of materials science lies in the intersection of innovation and sustainability. Scientists and engineers are constantly pushing the boundaries of materials research, developing new and improved methods for creating materials that are not only durable and functional but also environmentally friendly. This interdisciplinary approach is essential for creating a future where materials are designed with sustainability in mind from the initial design phase.

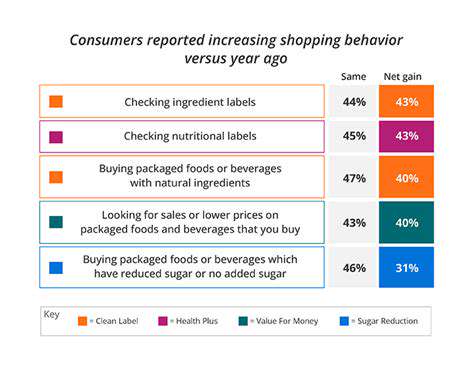

The Role of Consumer Choice in Shaping a Sustainable Future

Consumers play a pivotal role in driving the transition towards a circular economy. By making conscious choices about the products they purchase and the waste they generate, consumers can significantly influence the demand for sustainable materials and encourage companies to adopt more environmentally responsible practices. Supporting brands committed to ethical sourcing and recycling initiatives is a powerful way to advocate for change.

Education and awareness campaigns are crucial in empowering consumers with the knowledge and tools to make informed decisions. Understanding the life cycle of products, from raw materials to disposal, can empower consumers to choose products that minimize their environmental impact.

Economic Incentives and Policy Support: Fostering the Circular Economy

Government policies and economic incentives play a critical role in fostering a circular economy. By implementing regulations that incentivize recycling and promote the use of sustainable materials, governments can drive significant change. Policies that support research and development in sustainable materials science, while also providing financial assistance to companies embracing eco-friendly practices, can accelerate the transition to a more sustainable future.

Investing in infrastructure for waste collection and processing, along with supporting the development of new technologies for recycling and reuse, are vital steps in creating a system that effectively manages materials and minimizes waste.

Blending Bio-Based and Recycled Content: Synergistic Solutions

Blending Strategies for Enhanced Properties

Blending bio-based and recycled components offers a promising avenue for developing sustainable materials with improved properties compared to individual components. This approach allows for the optimization of material performance by leveraging the unique characteristics of each feedstock. For instance, bio-based polymers often exhibit excellent biodegradability and renewability, while recycled materials often possess lower costs and reduced environmental impact. By strategically combining these materials, manufacturers can potentially achieve a synergistic effect, leading to a more environmentally friendly and cost-effective product. Understanding the interplay between the different components is crucial for achieving the desired outcome.

Different blending strategies, including melt blending, solution blending, and in-situ polymerization, can be employed to create a homogeneous mixture of bio-based and recycled materials. The selection of the appropriate blending method depends on the specific properties of the target material and the compatibility of the different components. Careful consideration of processing parameters, such as temperature, shear rate, and mixing time, is critical to ensure uniform distribution of the components and avoid phase separation. This optimization process is crucial for maximizing the performance and minimizing the potential for degradation or incompatibility issues.

Challenges and Future Directions

Despite the potential benefits, challenges remain in achieving optimal blends of bio-based and recycled components. One significant hurdle is the inherent variability in the quality and properties of recycled materials, which can affect the final product characteristics. Moreover, ensuring compatibility between bio-based and recycled polymers can be complex, requiring careful selection of compatible polymers and additives. The development of new blending techniques and the optimization of existing ones are crucial for addressing these challenges.

Future research should focus on developing advanced blending methods that can effectively address the compatibility issues and maximize the synergistic effects of bio-based and recycled materials. Further investigation into the long-term performance of these blends in various environments is also critical. This includes understanding how the blends perform under different mechanical stresses, temperatures, and exposure to environmental factors. Understanding the degradation mechanisms and developing strategies to mitigate them will be essential for the widespread adoption of these materials in various applications.

Another important area of research is exploring the potential for incorporating functional additives to further enhance the properties of the blends. This could involve incorporating plasticizers, reinforcing fillers, or flame retardants to tailor the material properties for specific applications. This approach could unlock a wide range of possibilities for creating sustainable and high-performance materials.