The Role of Design in Maximizing Recycled Content

Optimizing Manufacturing Processes for Recyclability

Improving Efficiency Through Streamlined Processes

Optimizing manufacturing processes is crucial for enhancing efficiency and profitability. A streamlined approach to production can significantly reduce waste, increase output, and improve overall productivity. By identifying and eliminating bottlenecks in the workflow, manufacturers can achieve substantial gains in operational efficiency. This involves a careful analysis of the entire process, from raw material acquisition to finished product delivery.

Implementing lean manufacturing principles, such as just-in-time inventory management and 5S methodology, can yield significant improvements in efficiency. These methods help to minimize waste and maximize the utilization of resources, resulting in a more agile and responsive production system. A lean approach can dramatically reduce production costs and improve the overall quality of manufactured goods.

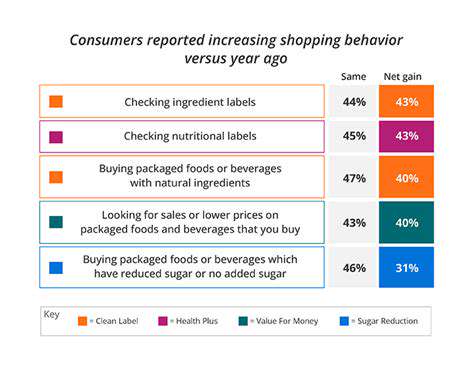

Reducing Costs Through Waste Minimization

Minimizing waste in manufacturing is paramount for cost reduction. Implementing strategies to eliminate material waste, labor waste, and time waste is essential for profitability. Waste often goes unnoticed, hiding within the day-to-day operations of a manufacturing facility. Identifying and addressing these hidden inefficiencies can lead to substantial cost savings.

Waste reduction initiatives can encompass various approaches, including optimized material handling, improved inventory control, and enhanced process design. Implementing these strategies can lead to significant savings in the long run, improving the bottom line for the manufacturing operation.

Enhancing Quality Through Precision Manufacturing

Precision manufacturing techniques are essential for enhancing product quality and reducing defects. By utilizing advanced technologies and methodologies, manufacturers can achieve greater accuracy and consistency in their production processes. This meticulous approach not only improves the final product but also minimizes the need for costly rework and repairs.

Leveraging Technology for Automation and Data Analysis

Integrating technology into manufacturing processes can significantly improve automation and data analysis capabilities. Automated systems can streamline tasks, increase production speed, and enhance overall efficiency. The use of robotics and automated guided vehicles (AGVs) can drastically reduce human error and increase productivity.

Data analysis plays a critical role in identifying trends, predicting potential issues, and optimizing production parameters. By leveraging data insights, manufacturers can make informed decisions, leading to improved decision-making and greater control over the entire manufacturing process.

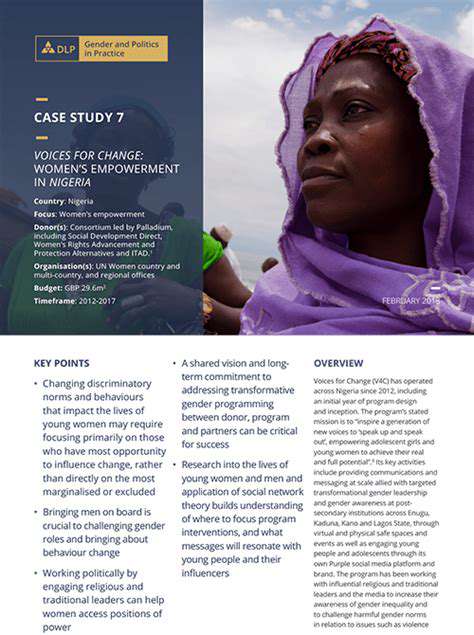

Improving Safety and Employee Engagement

Creating a safe and engaging work environment is crucial for maintaining high-quality production. Implementing safety protocols and providing employees with the necessary training and support will lead to a more productive and efficient workforce. A safe environment fosters a positive work culture where employees feel valued and empowered.

Employee engagement is directly linked to productivity and quality. Investing in employee training and development programs can enhance their skills and knowledge, leading to improved job satisfaction and increased motivation. A highly engaged workforce is more likely to identify and implement improvements in the manufacturing process.