Transparency in Supply Chains: Advanced Tracking Methods

Real-time Tracking and Enhanced Visibility

Modern supply chains require immediate visibility into every phase of product movement. Cutting-edge tracking solutions now monitor goods from factory floors to end consumers with unprecedented precision. GPS and IoT sensors deliver hyper-accurate location data, allowing companies to track shipments down to the meter, forecast delays before they occur, and implement preventive measures. This granular visibility transforms logistics planning from reactive to proactive.

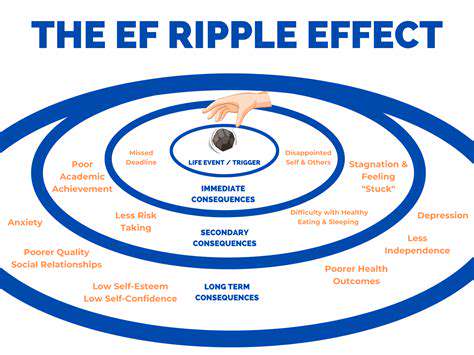

The transparency revolution extends beyond operations. When stakeholders share live updates, it strengthens partnerships through open communication channels. Customers benefit from accurate delivery estimates while suppliers gain insights for inventory planning. The ripple effects of comprehensive tracking create value across the entire commercial ecosystem.

Blockchain Technology for Secure and Transparent Records

Distributed ledger technology introduces an unforgeable documentation system for supply chains. Unlike traditional databases, blockchain creates permanent records that no single entity controls. Each material source, production batch, and shipping milestone gets cryptographically sealed in the chain. This eliminates disputes about product origins or handling history - particularly valuable for high-value or regulated goods.

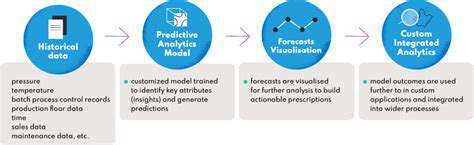

Artificial Intelligence (AI) for Predictive Analytics

Machine learning algorithms digest mountains of supply chain data to forecast challenges before they materialize. These systems identify subtle patterns in historical data that human analysts might miss, predicting everything from regional demand spikes to potential port congestion. Forward-thinking companies use these insights to pre-position inventory and adjust production schedules months in advance.

Internet of Things (IoT) for Enhanced Data Collection

Smart sensors embedded in shipping containers, warehouse shelves, and even individual products generate constant performance data. Temperature logs ensure pharmaceutical safety, vibration sensors detect rough handling, and weight monitors verify package contents. This real-time monitoring catches issues early - a refrigerated truck's failing cooling system triggers alerts long before products spoil.

Data Analytics for Informed Decision-Making

Advanced analytics platforms transform raw IoT data into actionable intelligence. Visualization tools highlight inefficient shipping routes, while machine learning models suggest optimal warehouse locations. The most sophisticated systems even simulate what-if scenarios, helping managers evaluate contingency plans before implementing them.

Sustainable Practices and Ethical Considerations

Today's consumers demand proof of responsible sourcing. Digital tracking solutions verify fair wages at supplier factories and document sustainable farming practices. Blockchain-based certification systems make greenwashing impossible by providing immutable evidence of environmental claims. This transparency builds brand loyalty among eco-conscious shoppers.

Improved Collaboration and Communication

Cloud-based platforms break down information silos between supply chain partners. Manufacturers see retailer inventory levels in real time, while logistics providers access production schedules to optimize fleet deployment. This shared visibility reduces costly redundancies - when everyone operates from the same data, the entire chain moves in sync.

Blockchain Technology: Securing Transparency and Traceability

Enhancing Transparency in Supply Chains

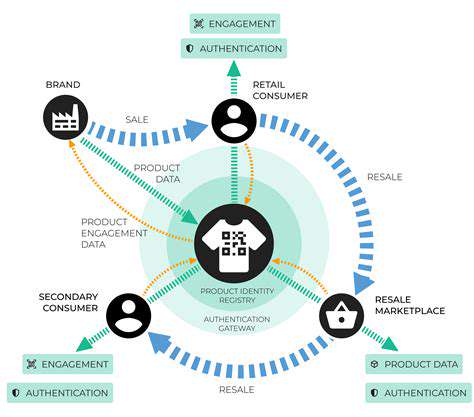

Distributed ledgers revolutionize supply chain transparency by creating a shared truth for all participants. Each transaction - from cotton harvesting to garment stitching - gets timestamped and linked to previous records. The system's design prevents retroactive alterations, giving importers confidence in organic certifications and retailers certainty about fair-trade claims.

End-to-end traceability satisfies modern consumer curiosity. Shoppers scanning QR codes might see a coffee bag's journey from Ethiopian hillside to supermarket shelf, complete with photos of the farming cooperative. This narrative transforms commodities into stories, adding value through transparency.

Improving Traceability and Accountability

Blockchain's chronological record-keeping shines during quality investigations. When contaminated produce appears, regulators trace it to the exact farm within minutes rather than weeks. The technology also deters corner-cutting - knowing every action creates a permanent record encourages compliance with safety standards.

For luxury brands, this system authenticates products throughout their lifecycle. A handbag's blockchain record might include the tanner's credentials, artisan workshop videos, and even second-hand ownership transfers. This verifiable history protects brand equity against counterfeiters.

Securing Data Integrity and Preventing Fraud

The cryptographic foundation of blockchain makes supply chain fraud exponentially harder. Drug manufacturers use it to verify active ingredient sources, while electronics companies authenticate conflict-free minerals. Each participant's digital signature creates an audit trail holding everyone accountable - a powerful deterrent against unethical practices.

In diamond trading, blockchain certificates accompany stones from mine to jewelry store. The immutable record includes microscopic inclusions that serve as nature's fingerprint, making substitution impossible. Similar applications protect art collectors, wine investors, and rare document traders.

The Future of Supply Chain Transparency: Predictive Analytics and AI

Improving Visibility and Efficiency

Next-generation supply chains will operate with crystal-clear visibility. Autonomous sensors will communicate via 5G networks, updating digital twin simulations in real time. These virtual replicas will allow managers to stress-test their networks against hurricanes, labor strikes, or sudden demand surges before real-world impacts occur.

AI optimization will reach new sophistication. Reinforcement learning algorithms will continuously adjust shipping routes based on weather patterns, fuel prices, and port congestion - sometimes redirecting cargo mid-journey for maximum efficiency. The environmental benefits will be substantial, with AI potentially reducing empty truck miles by 30% or more.

Enhancing Collaboration and Sustainability

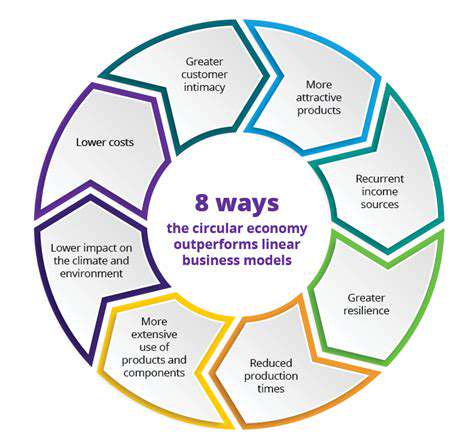

The supply chains of tomorrow will function as interconnected ecosystems rather than linear processes. Shared data platforms will enable spontaneous collaborations - a retailer's excess warehouse space might automatically accommodate a manufacturer's overflow inventory through smart contracts.

Sustainability metrics will become standard KPIs. Carbon accounting will extend to Tier 3 suppliers, with blockchain verifying emissions data at every step. Companies leading in transparency will premium-price their products, as consumers pay more for verified low-carbon footprints and ethical labor practices.

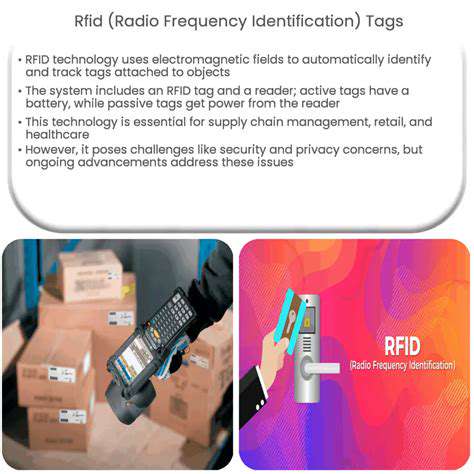

Circular economy principles will transform waste streams. RFID tags on packaging will direct used materials to optimal recycling facilities, while AI marketplaces match industrial byproducts with companies that can repurpose them. This closed-loop thinking will turn sustainability from cost center to profit driver.

Ethical auditing will evolve from periodic inspections to continuous monitoring. Wearable devices will anonymously aggregate worker wellbeing data, while satellite imagery tracks deforestation risks near supplier facilities. The most transparent companies will live-stream their supply chain operations, building unprecedented consumer trust.