Innovative Solutions for Hard to Recycle Textiles: Breaking Barriers: New Breakthroughs

The Delicate Dance of Textile Waste

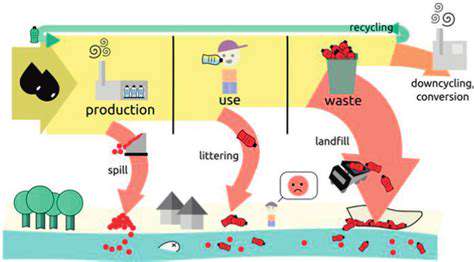

The textile industry, a cornerstone of global commerce, is facing a mounting crisis in managing its waste. Millions of tons of discarded clothing, fabrics, and other textile materials are piling up in landfills and incinerators each year, posing significant environmental challenges. This overwhelming amount of textile waste contributes to greenhouse gas emissions, water pollution, and the depletion of valuable resources. Addressing this issue requires a multifaceted approach that considers the entire lifecycle of textiles, from production to disposal.

The problem stems from a confluence of factors, including the fast fashion trend that prioritizes rapid production and consumption over durability and sustainability. Consumers often discard items after minimal use, exacerbating the volume of textile waste. Furthermore, the complex composition of many textiles, often including synthetic fibers and blends, makes recycling challenging. Current recycling methods are often inefficient and costly, further hindering progress.

Innovative Approaches to Textile Recycling

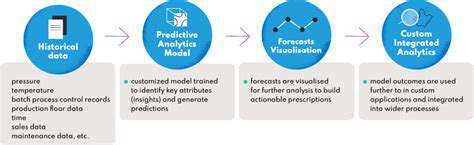

Fortunately, innovative solutions are emerging to tackle the textile recycling crisis. Researchers and companies are exploring new technologies and processes to improve the efficiency and effectiveness of textile recycling. These include advanced sorting techniques capable of separating different fiber types, and processes that break down synthetic materials into their constituent elements for reuse in new products. This approach not only reduces textile waste but also creates a circular economy model for the industry.

Another promising avenue is the development of new materials and designs that prioritize recyclability and durability. By incorporating recycled fibers into new garments and products, companies can reduce their environmental footprint and create a more sustainable supply chain. Furthermore, consumer education and awareness campaigns play a critical role in promoting responsible consumption and extending the lifespan of textiles.

Ultimately, solving the textile recycling crisis requires a collaborative effort encompassing industry, researchers, and consumers. By exploring innovative methods and adopting sustainable practices, we can move towards a future where textile waste is minimized, and the industry is environmentally responsible.

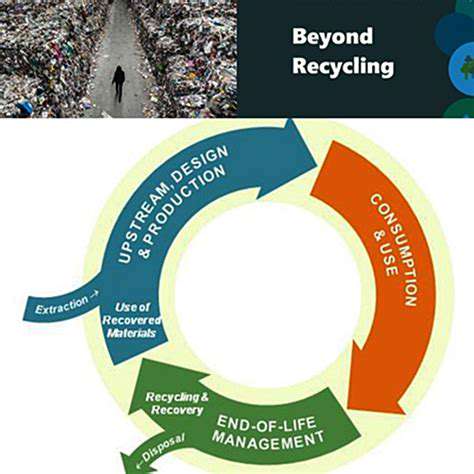

The current situation demands a shift in mindset, from a linear take-make-dispose model to a circular economy approach. This transformation is crucial for safeguarding the environment and promoting long-term sustainability within the textile sector.

Investing in research and development of new recycling technologies, coupled with consumer awareness campaigns and industry-wide adoption of sustainable practices, is paramount.

These innovative approaches hold the key to mitigating the environmental impact of textile waste and creating a more sustainable future for the industry.

Chemical Recycling: Decomposing Complex Fabrics

Chemical Recycling of Fabrics: A Deep Dive

Chemical recycling, a revolutionary approach to textile waste management, involves breaking down complex fabrics into their constituent components using chemical processes. This differs significantly from traditional mechanical recycling, which struggles with intricate blends and degraded fibers. The process offers a potential solution to the growing problem of textile waste, particularly for synthetic fabrics like polyester and nylon, which are notoriously difficult to recycle mechanically. This approach seeks to unlock the inherent value within these materials, enabling a more sustainable and circular fashion industry.

The key to chemical recycling lies in its ability to decompose the intricate molecular structures of these fabrics. By employing specific chemical agents, the process effectively separates the various components, making them suitable for reuse in new materials. This allows for the recycling of previously unusable materials, thereby reducing the reliance on virgin resources and minimizing the environmental footprint of textile production.

Challenges and Considerations in Chemical Recycling

While promising, chemical recycling faces significant hurdles. One major concern is the cost-effectiveness of the process compared to traditional methods. The intricate chemical procedures and specialized equipment often translate into higher upfront investments. Furthermore, the environmental impact of the chemicals used in the decomposition process needs careful scrutiny. The selection of environmentally benign chemicals is crucial to ensure a truly sustainable process.

Another critical consideration is the potential for chemical residues to contaminate the recycled materials. Rigorous testing and purification procedures are essential to guarantee the quality and safety of the recycled products. The development of standardized protocols and regulatory frameworks is imperative to oversee and manage the chemical recycling process for fabrics, ensuring responsible and sustainable practices throughout the supply chain.

Future Applications and Potential Benefits

The future of chemical recycling in the textile industry holds immense promise. As technology advances and costs decrease, this method could play a pivotal role in achieving a circular economy for textiles. The potential for recycling a wider range of fabrics, including mixed blends and complex materials, will open new avenues for sustainable fashion design and manufacturing. This innovative approach could significantly reduce textile waste and promote the reuse of valuable materials, contributing to a more environmentally conscious textile industry.

Beyond the direct recycling of fabrics, chemical recycling opens doors for innovative applications. The recovered components can be used to create new materials with enhanced properties, potentially leading to the development of high-performance textiles or specialized materials for various industries. This could revolutionize the entire textile supply chain, fostering a more sustainable and resourceful approach to material production.

Featured snippets are those concise answers that appear at the top of Google search results, often formatted in a way that clearly presents the answer. They are highly coveted by content creators because they significantly boost visibility and drive traffic to a website. Understanding how to structure your content to be eligible for featured snippets is crucial for SEO success.

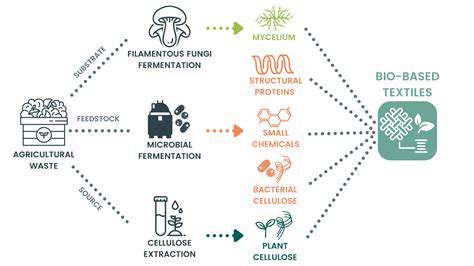

Bio-Based and Biodegradable Materials: A Sustainable Alternative

Bio-Based Polymers: A Growing Field

Bio-based polymers are derived from renewable resources like plants, algae, and agricultural waste, offering a sustainable alternative to petroleum-based plastics. This burgeoning field encompasses a wide range of materials, each with unique properties. From the familiar cellulose-based materials like paper and textiles to more advanced biopolymers, these materials hold great promise for reducing our reliance on fossil fuels and mitigating the environmental impact of plastic waste. The development and production of bio-based polymers are crucial for creating a more sustainable future in various industries.

The production of these materials typically involves less energy-intensive processes compared to their petroleum-based counterparts. This reduction in energy consumption contributes to a smaller carbon footprint, a critical factor in addressing climate change. Additionally, bio-based polymers often exhibit comparable mechanical properties to traditional plastics, making them suitable for a wide range of applications.

Biodegradability and Environmental Impact

A key advantage of bio-based materials is their biodegradability. Unlike traditional plastics, which can persist in the environment for hundreds of years, bio-based materials decompose naturally, minimizing their impact on landfills and ecosystems. This inherent characteristic is crucial in addressing the global plastic pollution crisis. The decomposition rate varies depending on the specific material and environmental conditions, but the overall trend is towards significantly reduced environmental harm compared to conventional plastics.

However, the environmental impact also depends on the entire lifecycle assessment. From the cultivation and processing of the raw materials to the end-of-life disposal, each stage needs careful consideration. Efficient waste management systems and responsible sourcing practices are essential to ensure the true sustainability of bio-based materials.

Applications and Technological Advancements

Bio-based and biodegradable materials are finding increasing applications in various sectors. Packaging industries are actively exploring alternatives to conventional plastics, aiming to reduce reliance on petroleum-derived materials. Furthermore, advancements in biopolymer technology are leading to improved performance characteristics, enabling broader use cases. This includes developing materials with enhanced strength, flexibility, and thermal stability, opening possibilities for applications in construction, automotive, and medical sectors.

Ongoing research and development are focused on optimizing the properties and production processes of bio-based materials. Scientists are working to create materials with improved mechanical properties, extended lifespans, and tailored functionalities to meet the demands of specific applications. This continuous innovation is vital for the widespread adoption and successful integration of bio-based solutions into our daily lives.

Challenges and Future Outlook

While the potential of bio-based and biodegradable materials is significant, challenges remain. Cost-effectiveness compared to conventional plastics is often a hurdle, although this gap is steadily narrowing with advancements in production techniques. Furthermore, ensuring consistent quality and performance across different applications requires further research and optimization. Standardization of testing methods and clear regulations are crucial to promote trust and adoption.

The future of bio-based and biodegradable materials looks promising. Continued research and development, coupled with supportive policies and investments, will drive innovation and accelerate the transition towards a more sustainable materials landscape. The collective effort from researchers, manufacturers, and consumers is essential for realizing the full potential of these eco-friendly alternatives and creating a more environmentally responsible future.